Abstract

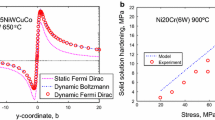

Creep theories of metals are based often upon constitutive relations for constant-stress, constant-temperature creep data. For variable stress and temperature processes, a hardening rule is required. In addition, a flow criterion is required for multiaxial states of stress. In this paper, creep-design procedures are evaluated for metal members subject to multiaxial-stress states and step changes in load and temperature. Tension-test data for copper alloy 360 (fre-cutting brass) and SAE 1035 steel for constant stress levels at three elevated temperatures, are approximated by four different forms of creep relations. Timehardening and strain-hordening rules are employed with reasonable success to describe the experimental creep deformations of tension specimens subjected to step changes in load and temperature. In addition, experimental data for torsion members of solid cross section subjected to step changes in load and temperature are described by means of two creep relations and the strain-hardening rule and flow criteria of von Mises and Tresca. Accurate description of the experimental data for SAE 1035 steel is obtained with the von Mises criterion. However, for free-cutting brass, poor correlation between theory and experiment is obtained with both the von Mises and the Tresca flow criteria. Further study of the behavior of free-cutting brass is indicated.

Similar content being viewed by others

Abbreviations

- σ r , σθ, σ z , τ rθ , τ θz , τ zr :

-

stress components in polar coordinates

- ∈ r , ∈ θ , ∈ z , γ rθ , γ θz , γ zr :

-

strain components in polar coordinates

- \(\dot \in _{pr} ,\dot \in _{p\theta } ,\dot \in _{pz}\) :

-

extensional-strain-creep rates

- \(\dot \gamma _{pr\theta } ,\dot \gamma _{p\theta z} ,\dot \gamma _{pzr}\) :

-

shear-strain-creep rates

- σ1, σ2, σ3 :

-

principal stresses

- \(\dot \in _{p1} ,\dot \in _{p2} ,\dot \in _{p3}\) :

-

principal-strain-creep rates

- σ m :

-

maximum stress that material has encountered [eq (8)]

- σ:

-

stress

- τ:

-

shear stress

- σ vm , σ T :

-

equivalent stresses according to von Mises and Tresca flow criteria, respectively

- ∈ p :

-

creep strain (\(\dot \in _p\) denotes creep-strain rate)

- σ vm , σ T :

-

equivalent creep strains according to von Mises and Tresca flow criteria, respectively (\(\dot \in _{vm} ,\dot \in _T\) denote associated creep rates)

- γ:

-

total shear strain [eq (16)] (γ e , γ p denote elastic and creep parts of γ)

- β:

-

unit angle of twist [eqs (16), (18), (19)], β e , β p denote elastic and creep parts of β)

- T :

-

temperature

- T a :

-

absolute temperature

- τ:

-

variable radius of torsion member

- R :

-

outer radius of solid torsion member

- t :

-

time

- E :

-

modulus of elasticity

- G :

-

elastic shear modulus

- J :

-

polar moment of inertia [eq (19)]

- M :

-

torque applied to torsion member

- N :

-

number of concentric ring elements for torsion member [eq (19)]

- N d :

-

number of data points for least-squares analysis

- N p :

-

number of constants in creep relationship

- N s :

-

number of creep parameters [eq (1)]

- S i :

-

parameters that characterize the creep process [eq (1)]

- f(T a ):

-

function of absolute temperature in creep relationship [eqs (2), (3), (4)]

- g(σ):

-

function of stress in creep relationship [eqs (2), (3), (5), (6), (7)]

- a, b, k, m, n, n c ,n p , σ p , σ c :

-

material constants in creep relations [eqs (2), (4), (5), (6), (7), (8)]

References

BLM Consultants, “Recommendations on the Calculation of Elastic and Creep Deformation of Nonhomogenous Turbine Disks of Variable Thickness,” Allison Appl. Mech. Report No. 27, Urbana, Ill. (1968).

Kanter, J. J., “The Problem of the Temperature Coefficient of Tensile Creep Rate,”Am. Inst. of Min. and Met. Engrs., Trans.,131,385 (1938).

Norton, F. H., Creep of Steel at High Temperatures, McGraw-Hill Book Company, Inc., New York (1929).

Nadai, A., Theory of Flow and Fracture of Solids, Vol. 2, McGraw-Hill Book Company, Inc., New York (1963).

Garofalo, F., “Fundamentals of Creep and Creep Rupture of Metals, The Macmillan Company, New York (1965).

Odovist, F. K. G., Mathematical Theory of Creep and Creep Rupture, Oxford University Press, London (1966).

Smith, J. O. andSidebottom, O. M., Inelastic Behavior of Load-Carrying Members, John Wiley and Sons, Inc., New York (1965).

Dharmarajan, S. and Sidebottom, O. M., “Inelastic Design of Load Carrying Members,” Part 1—Theoretical and Experimental Analysis of Circular Cross section Torsion-tension Members Made of Materials that Creep,” WADD Tech. Report 60-580 (1961).

Lietzke, M. H., “A Generalized Least Squares Program for the IBM 7090 Computer,”ORNL Report No. 3259, Oak Ridge Natl. Lab., Oak Ridge, Tenn. (1962).

Chu, S. C. and Sidebottom, O. M., “Creep of Metal Torsion-Tension Members Subjected to Nonproportionate Load Changes,” Paper presented at the SESA Spring Meeting, Huntsville, Ala., May 1970.

Pickel, T. W., Jr. “Flow Criteria and Constitutive Relations for the Numerical Analysis of Plane Stress Problems with Creep,”Ph.D. Thesis, University of Ill., Urbana, Ill. (1969).

Gubser, J. L. and Sidebottom, O. M., and Shammamy, M. R., “Creep Torsion of Prismatic Bars,” Joint Internatl. Conf. on Creep. 2-99-2-108 (1963).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Pickel, T.W., Sidebottom, O.M. & Boresi, A.P. Evaluation of creep laws and flow criteria for two metals subjected to stepped load and temperature changes. Experimental Mechanics 11, 202–209 (1971). https://doi.org/10.1007/BF02324216

Issue Date:

DOI: https://doi.org/10.1007/BF02324216