Abstract

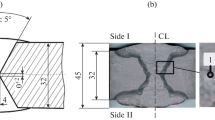

This paper presents measurements of the bulk residual stresses in 100-mm (4-in.) and 250-mm (10-in.) diam Schedule 80 piping weldments using strain-relief techniques. Both laboratory-welded specimens and field-welded specimens from reactors in service were studied. Axial bulk residualstress distributions were obtained at 45-deg intervals around the circumference. At each azimuthal position, the residual stresses were measured at seven axial positions: on the weld center line and 13, 20 and 25 mm to either side of the weld center line, on both the inside and outside surface. The specimens were parted out using a wire-feed electric-discharge machine, and the resulting strain relief was measured with electrical-resistance strain gages (120-deg rosettes). The bulk residual stresses obtained on the inside surface of the 100-mm weldments exhibit an oscillatory distribution with peak values above 275 MPa (40 ksi) and stress gradients normal to the weld on the order of 35 MPa/mm (127 ksi/in.).

Similar content being viewed by others

References

Review of chronology by M. Kennemui, Nuclear Regulatory Commission, at a meeting on BWR pipe cracking, O'Hare Hilton Hotel, Chicago, Illinois, March 4, 1975, sponsored by Electric Power Research Institute.

Klepfer, H. et al., Investigation of Cause of Cracking in Austenitic Stainless Steel Piping, Volume 1. Internal General Electric Report NEDO 21000-1 (July 1975).

Shack, W.J., Ellingson, W.A. and Pahis, L.E., “Topical Report on the Measurement of Residual Stresses in Type 304 Stainless Steel Piping Butt-Weldments,” Report submitted to Electric Power Research Institute by Argonne National Laboratory (Aug. 1978).

Bainbridge, A.T., “Residual Stresses Arising from Machining and Fabrication,” AGARD Conference Proceedings No. 43, Symposium on Engineering Practice to Avoid Stress Corrosion Cracking, Istanbul, Turkey, Oct. 1969.

Tall, L., “Residual Stresses in Welded Plates—A Theoretical Study,”Weld. Res. Suppl.,43,105–235 (Jan. 1964).

Vaidyanathan, S., Todaro, A.F. andFinnie, I., “Residual Stresses Due to Circumferential Welds,”J. Eng. Mater. Technol., ASME Trans. 95,233–237 (Oct. 1973).

Vaidyanathan, S., Weis, H. andFinnie, I., “A Further Study of Residual Stresses in Circumferential Welds,”J. Eng. Mater. Technol., ASME Trans.,95,283–242 (Oct. 1973).

Makhnenko, V.I., Shekera, V.M. andIzbenko, L.A., “Special Features of the Distribution of Stresses and Strains Caused by Making Circumferential Welds in Cylindrical Shells,”Autom. Weld.,23 (12),43–47 (Dec. 1970).

Muraki, T., Bryan, J.J. andMasubuchi, K., “Analysis of Thermal Stresses and Metal Movement During Welding, Parts I and II,”J. Eng. Mater. Technol., ASME Trans. Series H.,97,81–90 (Jan. 1975).

Procedure Specification IA-MA-88 for Gas Tungsten Arc Welding and Shielded Metal Arc Welding of Corrosion Resistant Steel Pipe, Fittings, Valves and Flanges in Group P, Number 8, as qualified by Phillips, Getschow Co., 1971, Revision Number 3.

Timoshenko, S. andWoinowsky-Krieger, S., “Theory of Plates and Shells,”McGraw-Hill Book Company New York (1959).

Rybicki, E.F., Rodabaugh, E.D., Groom, J.J. et al., “Residual Stresses at Girth-butt Welds in Pipes and Pressure Vessels,” Final Report to U.S. Nuclear Regulatory Commission. Report NUREG-0376 (Nov. 1977).

Author information

Authors and Affiliations

Additional information

Work supported by the Electric Power Research Institute.

Rights and permissions

About this article

Cite this article

Ellingson, W.A., Shack, W.J. Residual-stress measurements on multi-pass weldments of stainless-steel piping. Experimental Mechanics 19, 317–323 (1979). https://doi.org/10.1007/BF02324152

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF02324152