Abstract

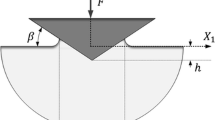

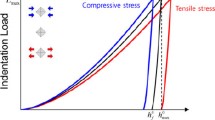

Static Vickers indentation tests were performed on Homalite specimens with an intent to obtain the residual stress distribution beneath the indentation. The indented specimens were placed in a circular polariscope to view the fringe patterns corresponding to the induced residual stress. Similitude analysis was later employed to identify the functional relationship between the various parameters related to an indentation test. The analysis resulted in a unified relationship that can assist in the determination of residual stress in nontransparent materials subjected to similar geometric and loading conditions. The shear stress contours provided here can also be used as guidelines to verify constitutive models under complex three-dimensional loads.

Similar content being viewed by others

References

Antis, G.R., Chantikul, P., Lawn, B.R. andMarshall, D.B., “A Critical Evaluation of Indentation Technique for Measuring Fracture Toughness: I. Direct Crack Measurements,”J. Am. Ceram. Soc.,64 (9)533–538 (1981).

Chantikul, P., Antis, G.R., Lawn, B.R., andMarshall, D.B., “A Critical Evaluation of Indentation Technique for Measuring Fracture Toughness: II. Strength Method,”J. Am. Ceram. Soc.,64 (9),539–543 (1981).

Cook, R.F. andPharr, G.M., “Direct Observation and Analysis of Indentation Cracking in Glasses and Ceramics,”J. Am. Ceram. Soc.,73 (4),787–817 (1990).

Lawn, B.R., Evans, A.A., andMarshall, D.B., “Elastic/Plastic Indentation Damage in Ceramics: The Median/Radial Crack System,”J. Am. Ceram. Soc.,63 (9–10),574–581 (1980).

Marshall, D.B., Lawn, B.R., andEvans, A.G., “Elastic-plastic Indentation Damage in Ceramics: The Lateral Crack System,”J. Am. Ceram. Soc.,65 (11),561–566 (1982).

Evans, A.G. andMarshall, D.B., “Wear Mechanisms in Ceramics,”Fundamentals of Friction and Wear of Materials, ed. D.A. Rigney, ASME, New York, 439 (1981).

Gruninger, M.F., Lawn, B.R., Farabaugh, E.N., andWachtman, J.B., Jr., “Measurement of Residual Stresses in Coatings on Brittle Substrates by Indentation Fracture,”J. Am. Ceram. Soc.,70, (5),344–348 (1987).

Lawn, B.R. andFuller, E.R., Jr., “Measurement of Thin-layer Surface Stresses by Indentation Fracture,”J. Mat. Sci.,19,4061–4067 (1984).

Yoffe, E.H., “Elastic Stress Fields Caused by Indenting Brittle Materials,”Phil. Mag. A,46,617–628 (1982).

Chiang, S.S., Marshall, D.B., andEvans, A.G., “The Response of Solids to Elastic/Plastic Indentation: I. Stresses and Residual Stresses, II. Fracture Initiation,”J. Appl. Phys.,53,298–311 (1982).

Chiang, S.S., Marshall, D.B., andEvans, A.G., “The Response of Solids to Elastic/Plastic Indentation: II. Fracture Initiation,”J. Appl. Phys.,53,312–317 (1982).

Zeng, K. andRowcliffe, D., “Experimental Measurement of Residual Stress Field Around a Sharp Indentation in Glass,”J. Am. Ceram. Soc.,77 (2),524–530 (1994).

Zeng, K. andRowcliffe, D.J., “Vickers Indentations in Glass—I. Residual Stress Fields and Iso-stress Contour Maps,”Acta. Metall. Mat.,43 (5),1935–1943 (1995).

Zeng, K., Soderlund, E., Giannakopoulos, A.E., andRowcliffe, D.J., “Controlled Indentation: A General Approach to Determine Mechanical Properties of Brittle Materials,”Acta. Metall. Mat.,44 (3)1127–1141 (1996).

Dally, J.W. andRiley, W.F., Experimental Stress Analysis, McGraw-Hill, New York (1991).

MATLAB, Version 5.0, The MathWorks, Inc. (1996).

ASTM, “C1327-96a: Standard Test Method for Vickers Indentation Hardness of Advanced Ceramics,” Annual Book of ASTM Standards, 1.03, ASTM, Easton, MD (1996).

Burger, C.P., “Photoelasticity,” Handbook on Experimental Mechanics, ed. A.S. Kobayashi, Prentice Hall, Englewood Cliffs, NJ (1987).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Anton, R.J., Miskioglu, I. & Subhash, G. Determination of resudual stress fields beneath a Vickers indentation using photoelasticity. Experimental Mechanics 39, 227–230 (1999). https://doi.org/10.1007/BF02323556

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF02323556