Abstract

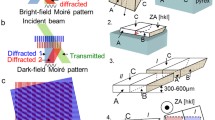

The scanning electron microscope (SEM) moiré method for microscopic measurements based on electron beam lithography and an SEM has been well developed. Although it has been a reliable method, some drawbacks exist: reinforcement effects, complicated processing and low sensitivity. To improve the SEM moiré method, new grating-casting techniques and a fringe-viewing technique must be developed. In this study, a carbonaceous grating technique and a total imaging technique are introduced. Accordingly, there are two techniques available for grating-casting (i.e., the carbonaceous grating technique and the existing lithography grating technique) and three techniques available for fringe viewing (i.e., the total imaging technique, the existing, monitor viewing technique and the existing photographic viewing technique). A total of six new imaging techniques of SEM moiré methods are available for microscopic measurements by combining one technique from each of the two groups. This study demonstrates the feasibility of the individual techniques and discusses the characteristics and limitations of each. Based on the presented total imaging technique, the sensitivity of the moiré method is only dependent on the frequency of specimen grating. Because it can be made as high as 10,000 lines/mm, the SEM moiré method can achieve sensitivity as high as 0.01 percent.

Similar content being viewed by others

References

Parks, V.J., “Geometric Moiré,”Handbook on Experimental Mechanics, ed. A.S. Kobayashi, Prentice Hall, Englewood Cliffs, NJ, 282–313 (1987).

Post, D., Han, B., andIfju, P., High Sensitivity Moiré—Experimental Analysis for Mechanics and Materials, Springer-Verlag, Berlin (1994).

McDonach, A., McKelvie, J., andWalker, C.A., “Stress-analysis of Fibrous Composites Using Moiré Interferometry,”Opt. Lasers Eng.,1 (2),85–105 (1980).

Morimoto, Y., Hayashi, T., andWada, K., “High-sensitivity Measurement of Strain by Moiré Interferometry,”JSME Int. J. Ser. I—Solid Mech. Strength Mat.,32,122–127 (1989).

Post, D., “Optical Interference for Deformation Measurements, Classical Holographic and Moiré Interferometry,”Mechanics of Nondestructive Testing, ed., W.W. Stinchcomb, Plenum Press, New York, 1–53 (1980).

Post, D., “Moiré Interferometry—Advances and Applications,” EXPERIMENTAL MECHANICS,31,276–280 (1991).

Han, B. andPost, D., “Immersion Interferometer for Microscopic Moiré Interferometry, EXPERIMENTAL MECHANICS,32,38–41 (1992).

Smith, H.I., Chinn, S.R., andDeGraff, P.D., “Application of Moiré Techniques in Scanning-electron-beam Lithography and Microscopy,”J. Vacuum Sci. Tech.,12,1262–1265 (1975).

Kishimoto, S., Egashira, M., Shinya, N., andCarolan, R.A., “Local Micro-deformation Analysis by Means of Microgrid and Electron Beam Moiré Fringe Method,”Proceedings of the 6th International Conference on Mechanical Behavior of Materials,4,ed. M. Jono and T. Inoue, Kyoto, Japan,661–666 (1991).

Dally, J.W. andRead, D.T., “Electron-beam Moiré,” EXPERIMENTAL MECHANICS,33,270–277 (1993).

Read, D.T. andDally, J.W., “Theory of Electron Beam Moiré,”J. Res. Natl. Inst. Stand. Tech.,101 (1),47–61 (1996).

Dally, J.W. andRead, D.T., “Micromechanics Study of the Effects of Damage on Interface Strains,”Novel Exp. Tech. Fract. Mech.,17 (6),1–11 (1993).

Read, D.T. andDally, J.W., “Local Strain Measurement by Electron Beam Moiré,”Advances Electron. Packag.,4,163–169 (1993).

Read, D.T. andDally, J.W., “Electron-beam Moiré Study of Fracture of a Glass-fiber-reinforced Plastic Composite,”J. Appl. Mech.,61,402–409 (1994).

Read, D.T. andDally, J.W., “Fatigue of Microlithographically-patterned Freestanding Aluminum Thin-film Under Axial Stresses,”J. Electron. Packag.,117 (1),1–6 (1995).

Read, D.T., Drexler, E., Bernard, E., Grosse, I., Benoit, J., DiTomasso, J., Holzhauer, D.P.R., and Stoklosa, M., “Thermomechanical Behavior of a High Density Polymer Overlay MCM Interconnect Structure: Experiments and Analysis,” Appl. Fract. Mech. Electron. Packag. Mat., EEP-11/MD-64, ASME, 251–261 (1995).

Drexler, E.S. andBerger, J.R., “Mechanical Deformation in Conductive Adhesives as Measured with Electron-beam Moiré,”J. Electron. Packag.,121 (2),69–74 (1999).

Drexler, E.S., “Reliability of A Flip-chip Package Thermally Loaded Between 55 Degrees C and 125 Degrees C,”J. Electron. Mat.,28,1150–1157 (1999).

Hren, J.J., “Specimen Contamination in Analytical Electron-Microscopy—Sources and Solutions,”Ultramicroscopy,3,375–380 (1978).

Bance, U.R., Drummond, I.W., Finbow, D., Harden, E.H., andKenway, P., “Hydrocarbon Contamination in Vacuum Dependent Scientific Instruments,”Vacuum,28,489–496 (1978).

Love, G., Scott, V.D., Dennis, N.M.T., andLaurenson, L., “Sources of Contamination in Electron-optical Equipment,”Scanning,4 (1),32–39 (1982).

Hirsch, P., Kassens, M., Puttmann, M., andReimer, L., “Contamination in a Scanning Electron-microscope and the Influence of Specimen Cooling,”Scanning,16,101–110 (1994).

Postek, M.P., “An Approach to the Reduction of Hydrocarbon Contamination in the Scanning Electron Microscope,”Scanning,18,269–274 (1996).

Nshaninan, T., Dove, R., andRajan, K., “In-situ Strain Analysis with High Spatial Resolution: A New Failure Inspection Tool for Integrated Circuit Applications,”Eng. Failure Anal.,3,109–113 (1996).

Folch, A., Servat, J., Esteve, J., Tejada, J., andSeco, M., “High-vacuum Versus ‘Environmental’ Electron Beam Deposition,”J. Vacuum Sci. Tech. B,14,2609–2614 (1996).

Kreuzer, P., “Formation and Examination of Self-supporting Contamination Filaments,”Optik,78,158–164 (1988).

Attwood, D.G. andHazzledine, P.M., “A Fiducial Grid for High-resolution Metallography,”Metallography,9,483–501 (1976).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Chen, H., Liu, D. Advances in scanning electron microscope moiré. Experimental Mechanics 41, 165–173 (2001). https://doi.org/10.1007/BF02323193

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF02323193