Abstract

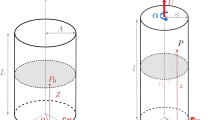

A photelastic analysis was carried out on plane polyester specimens containing a fatigue crack, in order to study the effect of plastic yielding around the crack tip on the elastic stress distribution in the vicinity of the crack. In general, results were in good agreement with values calculated for the case of a sharp-tipped crack. However, very near the crack tip, principal stresses obtained experimentally were slightly lower than calculated stresses, probably due to the bluntness of the fatigue crack. Also lines of constant stress tended to move behind the crack tip, in contrast with the calculated stresses, which occurred further forward over the field of investigation.

Similar content being viewed by others

Abbreviations

- x,y :

-

lateral and axial coordinates, respectively, with respect to the specimen axis, emanating from the crack tip

- σ p , σ q :

-

principal stresses

- σ o :

-

applied axial stress

- σ x , σ y :

-

lateral and axial normal stresses, respectively, with respect to the specimen axis

References

Dixon, J. R., “Computed Values of Elastic Stress around a Crack in an Infinite Plate under Tension”,NEL Report, No. 12, Natl. Engr. Lab., Glasgow (1961).

Wells, A. andPost, D., “The Dynamic Stress Distribution Surrounding a Running Crack—A Photoelastic Analysis,”Proc. SESA XVI (1),69–92 (1958).

Gerberich, W., “Stress Distribution About a Slowly Growing Crack Determined by Photoelastic-coating Method,Experimental Mechanics,2 (12),359–365 (1962).

Dixon, J. R. andVisser, W., “An Investigation of the Elasti-Plastic Strain Distribution around Cracks in Various Sheet Materials,”Symp. on Photoelasticity, ed. by M. M. Frocht, Pergamon Press, London, 231–250 (1963).

Dixon, J. R., “Stress Distribution around a Crack Loaded in Tension; Effect of Finite Width of Plate”,J. Roy. Aero. Soc.,64,141–145 (March 1960).

Assa, A., “A Photo-Elastic Analysis of the Stress Field Surrounding a Fatigue Induced Crack”,MSc Thesis, Technion, Israel Inst. of Tech., Haifa (1971).

Rice, J. R., “Mechanics of Crack Tip Deformation and Extension by Fatigue”, Fatigue Crack Propagation, ASTM STP 415, 247–309 (1967).

McEvily, A. J., Jr., Boettner, R. C. andJoshston, T. L., “On the Formation and Growth of Fatigue Cracks in Polymers”,Fatigue-An Interdisciplinary Approach, ed. by J. J. Burke, N. L. Reed andV. Weiss, Syracuse Univ. Press, Syracuse, 95–103 (1964).

Guernsey, R. andGilman, J., “Photoelastic Study of the Stress Near a Cleavage Crack”,Experimental Mechanics,1 (8),50–54 (1961).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Berkovits, A., Betser, A.A. & Assa, A. Photoelastic analysis of the stress field surrounding a fatigue crack. Experimental Mechanics 14, 64–68 (1974). https://doi.org/10.1007/BF02323128

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF02323128