Abstract

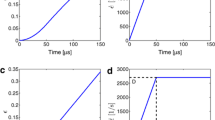

A technique is described by means of which torsional waves of large, essentially constant amplitude can be generated in an elastic bar. Waves with rise times of order 25 μs and maximum angular velocities of order 103 rad.s−1 have been achieved and used to test tubular specimens at shear-strain rates up to 15×103 s−1. Results are presented for mild steel tested at 2×103 s−1, and it is shown that the flow stress correlates well with the trend found at lower rates using conventional methods. The measured drop of stress at yield, however, was considerably smaller in the present tests than in earlier work; this is attributed to the generation of flexural waves which reach the specimen at the same time as the torsional wave.

Similar content being viewed by others

References

Kolsky, H., “An Investigation of the Mechanical Properties of Materials at Very High Rates of Loading,”Proc. Phys. Soc. B62,676 (1949).

Baker, W. E. andYew, C. H., “Strain-rate Effects in the Propagation of Torsional Plastic Waves,”Jnl. Appl. Mech.,33,917 (1966).

Campbell, J. D. andDowling, A. R., “The Behaviour of Materials Subjected to Dynamic Incremental Shear Loading”,Jnl. Mech. Phys. Solids,18,43 (1970).

Duffy, J., Campbell, J. D., andHawley, R. H., “On the Use of a Torsional Split Hopkinson Bar to Study Rate Effects in 1000-0 Aluminum”,Jnl. Appl. Mech.,38,83 (1971).

Lindholm, U. S., “Some Experiments with the Split Hopkinson Pressure Bar”,Jnl. Mech. Phys. Solids,12,317 (1964).

Pope, D. P., Vreeland, T., andWood, D. S., “Machine for Producing Square Torsion Pulses of Microsecond Duration”,Rev. Scientific Instruments,35,1351 (1964).

Campbell, J. D. and Harding, J., “The Effect of Grain Size, Rate of Strain, and Neutron Irradiation on the Tensile Strength of α-Iron”, Response of Metals to High Velocity Deformation, Interscience Press, 51 (1961).

Harding, J. “Tensile Impact Testing by a Magnetic Loading Technique”,Jnl. Mech. Engng. Sci.,7,163 (1965).

Klepaczko, J., “The Strain Rate Behavior of Iron in Pure Shear”,Int. Jnl. Solids Structures,5,533 (1969).

Yen, C. C. S. andYew, C. H., “Dynamic Shear Stress-Strain-Strain Rate Relations of Iron”,Jnl. of Materials,4,324, (1969).

Campbell, J. D. andTsao, M. C. C., “On the Theory of Transient Torsional Wave Propagation in a Circular Cylinder”,Quart. Jnl. Mech. and Applied Math,25,173 (1972).

Campbell, J. D. and Lewis, J. L., “The Development and Use of a Torsional Split Hopkinson Bar for Testing Materials at Shear Strain Rates up to 15000 sec −1 ,” Report No. 1080,69, Department of Engineering Science, University of Oxford (1969).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Lewis, J.L., Campbell, J.D. The development and use of a torsional Hopkinson-bar apparatus. Experimental Mechanics 12, 520–524 (1972). https://doi.org/10.1007/BF02320749

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF02320749