Abstract

Machine assemblies can be prestressed (1) to eliminate stress gradients and (2) to increase fatigue life.

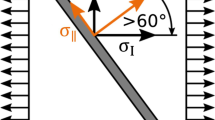

Where prestressing is used to reduce stress gradients, the geometry is usually simple and good mathematical models are available for design purposes. The instances where fatigue life is the prime consideration are difficult to analyze because of asymmetry and variable boundary conditions. However, the interference prestress can be determined from an approximate model. The approximate solution indicates that the normal stress at the interface of a bolt-hole assembly varies almost linearly with diametral interference.

When a tensile field is added to an interference prestress, even approximate techniques falter. Quantitative agreement with strain-gage data can be made at a point and for the initial loading cycle only. After several cycles, the experimental value of cycle-stress variation at the interface approximates the average applied tensile stress. The calculated value is twice as great. Stresses due to interference fits can be predicted, and prestressed bolted joints designed with greater confidence.

Similar content being viewed by others

References

Savin, G. N., Stress Concentration Around Holes, Pergamon Press, New York, 105 and 121 (1961).

Love, T. S., “Study of Stress Patterns Around Prestressed Holes Subject to Various Loading Parameters,” General Dynamics Fort Worth Division Report ERR-FW-436 (December 1965).

Lowe, T. S., “Photoelastic Analysis of Prestressed Holes,” General Dynamics Fort Worth Division Memo (September 1968).

Sokolnikoff, I. S., Mathematical Theory of Elasticity, McGraw-Hill Book Co., Inc., New York, 282 and 286 (1956).

Jeffery, G. B., “Plane Stress and Plane Strain in Bi-Polar Coordinates,”Phil. Trans. Roy. Soc., Ser. A,221,265–293 (1921).

Wheeler, O. E., “Elastic Stresses Around Bolt Holes,” General Dynamics Fort Worth Division Report MRL-75 (November 1968).

Peterson, R. E., Stress Concentration Design Factors, John Wiley & Sons, Inc., New York (1953).

Additional information

J. A. Regalbuto is a Staff Scientist in the Applied Research Laboratory and O. E. Wheeler is a Project Structures Engineer in the Advanced Structural Dynamics Group at General Dynamics, Fort Worth Division.

This work was supported by a General Dynamics Research Program.

Rights and permissions

About this article

Cite this article

Regalbuto, J.A., Wheeler, O.E. Stress distributions from interference fits and uniaxial tension. Experimental Mechanics 10, 274–280 (1970). https://doi.org/10.1007/BF02320678

Issue Date:

DOI: https://doi.org/10.1007/BF02320678