Abstract

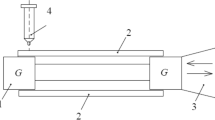

Incremental and total-strain theories have recently been used by the authors to obtain numerical solutions for the hydrostatic bulging of circular diaphragms. These solutions have incorporated the effects of anisotropy in the direction of the thickness of the sheet. This investigation was conducted to obtain test data on aluminum-killed steel sheets which contain the above mentioned anisotropy and to compare these data with the predictions of the incremental and total-strain theories solutions. The results show that the incremental theory is in better agreement with test data than the total-strain theory. Strain-path data for several volume elements shows that each volume element follows an approximately proportional strain path. However, the strain paths obtained from the total-strain theory are in gross disagreement with the data.

Similar content being viewed by others

References

Wang, N. M. andShamamy, M. M., “On the Plastic Bulging of a Circular Diaphragm by Hydrostatic Pressure,”Jnl. of Mech. and Phys. of Solids,17,43–61 (1969).

Drucker, D. C., “Stress-strain Relations in the Plastic Range: A Survey of Theory and Experiment,”Report No. NR-041-032, Grad. Div. of Appl. Math., Brown University, Providence, R. I. (December1950).

Gleyzal, A., “Plastic Deformation of a Circular Diaphragm Under Pressure,”Trans. Am. Soc. of Mech. Engrs.,70,288–296 (June1948).

Weil, N. A. andNewmark, N. M., “Large Plastic Deformations of Circular Membranes,”Jnl. of Appl. Mech.,22,533–538 (June1955).

Woo, D. M., “The Analysis of Axisymmetric Forming of Sheet Metal and the Hydrostatic Bulging Process,”Internatl. Jnl. of Mech. Sci.,6,303–317, (1964).

Mellor, P. B., “Stretch Forming Under Fluid Prescure,”Jnl. of Mech. and Phys. of Solids,5,41–56, (1956).

Storakers, B., “Finite Plastic Deformation of a Circular Membrane Under Hydrostatic Pressure,”Internatl. Jnl. of Mech. Sci.,8,619–628, (1966).

Hill, R., “A Theory of the Plastic Bulging of a Metal Diaphragm by Lateral Pressure,”Philosophical Magazine,41, (7),1133–1142, (1950).

Brown, W. F. andSachs, G., “Strength and Failure Characteristics of Thin Circular Membranes,”Trans. Am. Soc. of Mech. Engrs.,70,241–251, (1948).

Brown, W. F. andThompson, F. C., “Strength and Failure Characteristics of Metal Membranes in Circular Bulging,”Trans. Am. Soc. of Mech. Engrs.,71,575–585, (1949).

Hill, R., The Mathematical Theory of Plasticity, Oxford University Press, Oxford (1950).

Bramley, A. N. andMellor, P. B., “Some Strain-Rate and Anisotropy Effects in the Stretch-Forming of Steel Sheet,”Internatl. Jnl. of Machine tool Design Rsch.,5,43–55, (1965).

Author information

Authors and Affiliations

Additional information

M. M. Shamamy, formerly of General Motors Research Laboratories, is presently associated with Trinity College and Rennselaer Polutechnic Institute, hartford, Conn. 06106.

Rights and permissions

About this article

Cite this article

Shamamy, M.M., Wang, N.M. Comparison of experimental and theoretical results for the hydrostatic bulging of circular sheets. Experimental Mechanics 11, 71–75 (1971). https://doi.org/10.1007/BF02320623

Issue Date:

DOI: https://doi.org/10.1007/BF02320623