Abstract

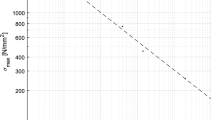

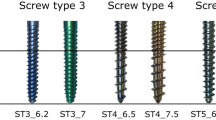

A satisfactory method was developed for evaluating the holding characteristics of fasteners in bone. Using this method in over 100 tests, the ultimate pull-out forces and shear stresses were determined for two sizes of sheet-metal type of screws with various interference fits, for a commercial orthopedic self-tapping screw, and for two sizes of machine screws in tapped bone, each at five sections of equine metacarpus. The ultimate pull-out force was maximum at the midlength of the bone, and minimum at the distal end. In general, the failure mechanisms were bone-thread shear for low pull-out forces, bone splitting at intermediate pull-out forces, and bone fragmentation at high pull-out forces. The failure mechanisms of the bone indicate that orthopedic fasteners should possibly not be designed for maximum holding force.

Similar content being viewed by others

Abbreviations

- d :

-

dimension of metacarpus cross section, in.

- D d :

-

drill diameter, in.

- D i :

-

minor diameter of screw, in.

- D o :

-

major diameter of screw, in.

- F :

-

force, kips

- F u :

-

ultimate force, kips

- i :

-

interference,D o −Dd/D o −Di, percent

- I :

-

interference,D o −Dd/D o , percent

- L :

-

total length of metacarpus, in.

- s :

-

fraction of length from proximal end, percent

- τ u :

-

ultimate shear stress, ksi

- δ:

-

displacement, in.

References

Bynum, D., Jr., Ledbetter, W. B., Boyd, C. L. and Ray, D. R., “Compression Properties of Equine Third Metacarpal Bone,” paper presented at the annual meeting of Soc. of Engrg. Sci., St. Louis, Mo. (Nov. 1969).

Boyd, C. L., Bynum, D., Jr., Ledbetter, W. B. and Ray, D. R., “Bone Properties and Fracture Propagation,” Proc. 15th Ann. Conv., Am. Assoc. Equine Practitioners, 85–97 (Dec. 1, 1969).

Bynum, D., Jr., “Bone Splices and Fracture Phenomenon,” presentation given to SESA Gulf Coast Section, Houston, Texas (Dec. 11, 1969).

Bynum, D., Jr., Ray, D. R., Boyd, C. L. and Ledbetter, W. B., “Capacity of Installed Commercial Bone Fixation Plates,” Am. Jnl. Vet. Res. (in press).

Bynum, D., Jr., Ray, D. R., Ledbetter, W. B. and Boyd, C. L., “Torsional Properties of Equine Metacarpus,” Jnl. Matls.,6 (1) (Mar. 1971).

Bynum, D., Jr., Ledbetter, W. B., Boyd, C. L. and Ray, D. R., “Flexural Properties of Equine Metacarpus,” Jnl. Biomedical Matls. Res. (in press).

Bynum, D., Jr., Ledbetter, W. B., Boyd, C. L. andRay, D. R., “Parametric SCF in Greenstick Fracture,”Experimental Mechanics,10 (11),474–480 (Nov.1970).

ASTM Newsfront in Technigram section, Matls., Res. and Stds. (Dec. 1969) pl.

Bechtol, C. O., Ferguson, A. B. andLaing, P. G., Metals and Engineering in Bone and Joint Surgery, Williams and Wilkins, Co., Baltimore, Md. (1959).

Oberg, E., andJones, F. D., Machinery's Handbook, 15th ed., Inaustrial Press, New York, N. Y. (1956).

Author information

Authors and Affiliations

Additional information

was formerly Engineering Research Associate, College of Engineering, Texas A & M University.

Rights and permissions

About this article

Cite this article

Bynum, D., Ledbetter, W.B., Boyd, C.L. et al. Holding characteristics of fasteners in bone. Experimental Mechanics 11, 363–369 (1971). https://doi.org/10.1007/BF02320538

Issue Date:

DOI: https://doi.org/10.1007/BF02320538