Abstract

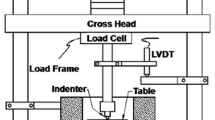

Ball-indentation experiment ware performed with A723 steel of 100- to 1200-MPa ultimate strength. Results are compared with conventional tension tests and with an elastic-plastic finite-element model of the ball indentation. Finite-element analysis shows the ball-indentation process to be insensitive to friction effects. Comparison of indentation and conventional tests shows that slip-line field analysis closely predicts the ball contact stress. The indentation tests gave an accurate measure of ultimate tensile strength because of the following test procedures: using a large ball size and a fixed ratio of indentation depth to ball size; accounting for directional material properties; accounting for extraneous system deflections.

Similar content being viewed by others

References

Metals Handbook, ed. Taylor Lymann, The Amer. Soc. for Metals, 93–105 (1948).

Hill, R., The Mathematical Theory of Plasticity, Oxford Univ. Press, 254–261 (1950).

George, R.A., Dinda, S. and Kasper, A.S., “Estimating Yield Strength From Hardness Data,” Metal Progress, 30–35 (May 1976).

Haggag, F.M. andLucas, G.E., “Determination of Luders Strains and Flow Properties in Steels From Hardness/Microhardness Tests, Met. Tans. A,14,1607–1613 (1983).

Underwood, J.H., “Residual-stress Measurement Using Surface Displacements Around an Indentation,”Experimental mechanics 13 (9),373–380 (Sept.1972).

“Standard Test Method for Plane-Strain Fracture Toughness of Metallic Materials, E399-83,” 1984 Annual Book of ASTM Standards,03.01,519–554 (1984).

“Standard Methods of Tension Testing of Metallic Materials, E8-83,” 1984 Annual Book of ASTM Standards,03.01,130–150 (1984).

Roark, A.J. andYoung, W.C., “Formulas for Stress and Strain, McGraw-Hill, New York, 516 (1975).

The NASTRAN Theoretical Manual, Level 17.5, NASA SP-221(05), Nat. Aero. and Space Admin., Section 3.8 (Dec. 1980).

Draper, N.R. andSmith, H., “Applied Regression Analysis, John Wiley, New York, 90–91 (1966).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Underwood, J.H., O'Hara, G.P. & Zalinka, J.J. Analysis of elastic-plastic ball indentation to measure strength of high-strength steels. Experimental Mechanics 26, 379–385 (1986). https://doi.org/10.1007/BF02320154

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF02320154