Abstract

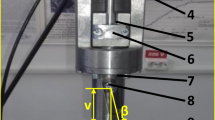

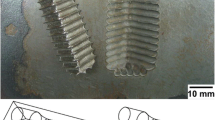

A unique tension-torsion fatigue test set up is described that allows strain-controlled tests at temperatures exceeding 649°C. The machine uses a large die set as a load frame resulting in lower cost and superior parallel positioning of the crossheads. Disposable weld-on grips were found to be cost effective for elevated-temperature testing. A new extensometer using commercially available capacitance probes was developed which can operate at the elevated temperature without cooling. Capacitance ring probes were utilized in an attempt to measure through-thickness strains. The characteristic behavior of the ring probes is discussed. Design modifications needed to make a successful measurement of through-thickness strains at elevated temperatures are presented.

Similar content being viewed by others

References

Taira, S., Inoue, T. andTakahashi, M., “Low Cycle Fatigue Under Multiaxial Stresses,”Proc. Jap. Congr. on Test. Mat.,9–10,18–23 (1966–67).

Lamba, H. S. andSidebottom, O. M., “Proportional Biaxial Cyclic Hardening of Annealed Oxygen-Free High-Conductivity Copper,”J. Test. and Eval.,6 (4),260–267 (July1978).

Zamrik, S. Y. andBilir, O. G., “Analysis of Biaxial-Fatigue Damage at Elevated Temperature,”Experimental Mechanics,16 (10),373–382 (1976).

Penn, R. W., Fong, J. T. and Kearsley, E. A., “Experience in Data Acquisition and Reduction for a Biaxial Mechanical Testing Program,” Use of Computers in the Fatigue Laboraotry, ASTM STP 613, ed. H. Mindlin and R. W. Landgraf, Amer. Soc. for Test. and Mat. (1976).

Brown, M. W. andMiller, K. J., “A Biaxial Fatigue Machine for Elevated Temperature Testing,”J. Test. and Eval.,9 (4),202–208 (July1981).

Lohr, R. D. andEllison, E. G., “Biaxial High Strain Fatigue Testing of 1 Cr-Mo-V Steel,”Fatigue of Engineering Material and Structures,3,19–37 (1979).

Fash, J. W., Socie, D. F. and McDowell, D. L., “Fatigue Life Estimates for a Simple Notched Component Under Biaxial Loading,” presented at ASTM Int. Symp. on Biaxial/Multiaxial Fatigue, San Francisco, CA (1982).

Brown, M. W., “Torsional Stresses in Tubular Specimen,”J. Strain Analysis for Eng. Design,13,23–28 (Jan.1978).

Blass, J. J., “Multiaxial Creep and Fatigue Damage Estimation for Type 304 Stainless Steel,” Oak Ridge Nat. Rep., ORNL/PM-6438.

Brown, M. W. andMiller, K. J., “A Biaxial Fatigue Machine for Elevated Temperature Testing,”J. Test. and Eval.,9 (4),202–208 (July1981).

Kanazawa, K., Miller, K. J. and Brown, M. W., “Low-Cycle Fatigue Under Out-of-Phase Loading Conditions,” J. Eng. Mat. and Tech., 222–228 (July 1977).

Wood, W., “Yield and Second-order Effects Induced by Cyclic Strain in Copper Under Tension,”Acta Met.,15,841–846 (May 1967).

Lohr, R. D. andEllison, E. G., “A Simple Theory for Low Cycle Multiaxial Fatigue,”Fatigue of Engineering Material and Structures,3,1–17 (1980).

Zamrik, S. Y., “An Investigation of Strain Cycling Behavior of 7075-T6 Aluminium Under Combined State of Strain,” 3rd Annual Progress Rep., Pennsylvania State Univ. (1967).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Jordan, E.H., Chan, C.T. A unique elevated-temperature tension-torsion fatigue test rig. Experimental Mechanics 27, 172–183 (1987). https://doi.org/10.1007/BF02319471

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF02319471