Abstract

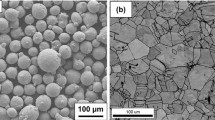

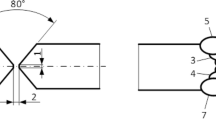

A series of isothermal low-cycle fatigue studies of small to extremely small-volume solder joints has been conducted. These solder microjoints were designed and fabricated using processing which duplicates the microelectronics interconnection structures that might be used in high density, highly integrated flip-chip packaging and all fatigue tests were conducted in fully reversed simple shear both with and without dwells at maximum strain. Results of low-cycle fatigue tests of both single and double-bump 95/5 Pb/Sn solder microjoints in the form of Manson-Coffin (plastic strain amplitude versus fatigue life) plots and post-test failure mode analysis (FMA) carried out using scanning electron microscope (SEM) fractography are presented and evaluated.

Similar content being viewed by others

References

Norris, K.C. andLandzberg, A.H., “Reliability of Controlled Collapse Interconnections,”IBM J. of Research and Development,13 (3),266–271 (1964).

Fox, L.R., Sofia, J.W. andShine, M.C. “Investigation of Solder Fatigue Acceleration Factors,”IEEE Trans. on Components, Hybrids and Manufacturing Technology, CHMT-8 (2),275–282 (1985).

Hall, P.M., Dudderar, T.D. andArgyle, J.F., “Thermal Deformations Observed in Leadless Ceramic Chip Carriers Surface Mounted to Printed Wiring Boards,”IEEE Trans. on Components, Hybrids and Manufacturing Technology, CHMT-6,544–557 (1983).

Hall, P.M., “Forces, Moments and Displacements During Thermal Chamber Cycling of Leadless Ceramic Chip Carriers Soldered to Printed Boards,”IEEE Trans on Components, Hybrids and Manufacturing Technology, CHMT-7 (4),314–327 (1984).

Manson, S.S., Thermal Stress and Low-Cycle Fatigue, Krieger, Florida, 155–192 (1966).

Coffin, L.F., Jr., “Fatigue Life Predictions at Elevated Temperature,” Proc. Joint Japan-USA Seminar on Strength and Structure of Solid Materials, ed. H. Miyamoto et al. and V. Weiss et al., Noordhoff Intl., 185–208 (1974).

Nir, N., Dudderar, T.D., Wong, C.C. andStorm, A.R., “Fatigue Properties of Microelectronics Solder Joints,”Trans. ASME, J. Electronic Packaging,113,92–101 (1991).

Solomon, H.D., “Low-Frequency, High Temperature Low Cycle Fatigue of 60Sn-40Pb Solder,”Low Cycle Fatigue, ASTM STP 942, ed. H.D. Solomon, G.L. Halford, L.R. Kaisand andB.N. Leis, ASTM, Philadelphia, 342–370 (1988).

Solomon, H.D., “Room Temperature Low Cycle Fatigue of a High Pb Solder (Indalloy 151),” Proc. 2nd ASM Electronic Materials and Processing Conf., 135–146 (1989).

Satoh, R., Arakawa, K., Harada, M. andMatsui, K., “Thermal Fatigue Life of Pb−Sn Alloy Interconnections,”IEEE Trans. on Components, Hybrids and Manufacturing Technology, CHMT-14 (1),224–232 (1991).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Dudderar, T.D., Nir, N., Storm, A.R. et al. Isothermal low-cycle fatigue testing of microscale solder interconnections. Experimental Mechanics 32, 11–20 (1992). https://doi.org/10.1007/BF02317978

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF02317978