Abstract

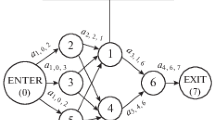

Scheduling methods are proposed for a class of flexible manufacturing systems consisting of machine centers served by a cyclic conveyor. The minimization of finish time is considered as the optimization criterion. An optimal algorithm is proposed for the minimum conveyor speed (S=1) for a particular system in the class under consideration. Scheduling algorithms based on a job matching principle, that are developed for the general systems, yield good results particularly for low conveyor speeds.

Similar content being viewed by others

References

K.R. Baker,Introduction to Sequencing and Scheduling (Wiley, New York, 1974).

R.W. Conway, W.L. Maxwell and L.W. Miller,Theory of Scheduling (Addison-Wesley, Reading, Mass, 1967).

E.G. Coffman, Jr. (ed),Computer and Job-Shop Scheduling Theory (Wiley, New York, 1976).

S. French,Sequencing and Scheduling (Wiley, New York, 1982).

M. Galouzeau and P. Siegel, Simulation d'une ligne flexible d'assemblage, Research report, Laboratoire d'Automatique, Ecole Nationale Superieure d'Ingenieurs Electriciens de Grenoble, France, 1984.

G.K. Huntchinson, Flexible manufacturing systems in the United States, Management Research Center, The University of Wisconsin-Milwaukee, WI, 1979.

C. Sriskandarajah, L'ordonnancement dans les ateliers: complexite et algorithmes heuristiques, Doctorate Thesis, Laboratorie D'Automatique, Ecole Nationale Superieure d'Ingenieurs Electriciens de Grenoble, France, 1986.

C. Sriskandarajah, P. Ladet and R. Germain, Scheduling methods for a manufacturing system, in:Flexible Manufacturing systems: Methods and Studies, ed. Andrew Kusiak (North-Holland, Amsterdam, 1986) pp. 173–189.

C. Sriskandarajah, P. Ladet and S.P. Sethi, A scheduling method for a class of flexible manufacturing system,Proceedings of the 3rd International Conference on Advances in Production Management Systems (APMS '87), Winnipeg, Canada, 1987, pp. 3–18.

Author information

Authors and Affiliations

Additional information

This research is supported in part by NSERC Grant A4619 and Manufacturing Research Corporation of Ontario.

Rights and permissions

About this article

Cite this article

Sriskandarajah, C., Sethi, S.P. & Ladet, P. Scheduling methods for a class of flexible manufacturing systems. Ann Oper Res 17, 137–161 (1989). https://doi.org/10.1007/BF02096602

Issue Date:

DOI: https://doi.org/10.1007/BF02096602