Summary

The copolymer of ethylene and propylene possesses a sufficiently high thermo-oxidative resistance, making it possible to study its viscous properties, determine the appearance of elastic turbulence and wall slippage and to measure the rate of the latter over a wide interval of temperatures ranging from room temperature to 260 °C.

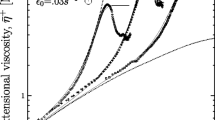

At low shear stresses and rates the copolymer behaves like aNewtonian liquid with a viscosity of about 108 poise at room temperatures.

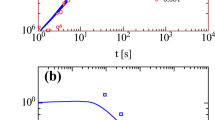

Elastic turbulence and wall slippage are displayed in sharp form when the viscosity of the copolymer is lowered to its critical value, which depends very little on the temperature and may be accepted as averaging 2.2×104 poise. The corresponding critical shear stress values vary about 10-fold. The criteria of appearance of elastic turbulence suggested in (12, 14) do not agree with experimental data. The entrance losses during the flow of the copolymer through capillaries are low right until elastic turbulence sets in, after which it becomes practically impossible to measure them by the method of capillaries of different length. The average wall slippage rate values of the copolymer at shear stresses above 106 dyne/cm2 amount to tens of cm/sec. They increase very abruptly with rising temperature.

The temperature dependence of the viscosity and the dynamic characteristics of the copolymer indicate that it has a phase transition at temperatures of about 100–120 °C, which must be related to melting of blocks contained in the copolymer macromolecules, having a structure close to that of high-pressure polyethylene. This shows that the rheological method of studying block-type polymer and grafted polymers is promising.

Similar content being viewed by others

References

Vinogradov, G. V. andN. V. Prozorovskaya, Plasticheskie Massy5, 50 (1964).

Vinogradov, G. V. andN. V. Prozorovskaya, Rheol. Acta3, 156 (1964).

Ivanova-Choomakova, L. V. andP. A. Rebinder, Kolloidniy Zhurnal18, 540 (1956).

Vinogradov, G. V. andJ. G. Janovski, Zavodsk. Lab.31, 115 (1965).

Vinogradov, G. V. andI. M. Belkin, J. Polymer Sci.3A, 917 (1956).

Vinogradov, G. V. andA. Ja. Malkin, J. Polymer Sci.4, Part A-2, 135 (1966).

Jun, Vi, et al., SPE Transaction4, 4 (Oct), 295–305 (1964).

Vinogradov, G. V. andV. N. Manin, Kolloid-Z. u. Z. Polymere201, 2 93–98 (1965).

Vinogradov, G. V., A. Ja. Malkin andA. I. Leonov, Koll.-Z. u. Z. Polymere191, 25 (1963).

Bagley, E. B., Trans. Soc. Rheol.,5, 354 (1961).

Tordella, J.-P., J. Polymer Sci.7, 215 (1963).

Bartos, O., J. Appl. Phys.35, 9, 2767 (1964).

Malkin, A. Ja. andG. V. Vinogradov, J. Appl. Polymer Sci.10, 767 (1966).

Overdiep, W. S. andD. W. Van Krevelen, J. Appl. Polymer Sci.9, 2779 (1965).

Metzner, A. B., Ind. Eng. Chem.50, 1577 (1958).

Hutton, J. F., Proc. Royal Soc.287, 222 (1965).

Mooney, M., J. Rheology2, 210 (1931).

Vinogradov, G. V. andV. V. Sinitsyn, Dokl. Akad. Nauk. SSSR86, 573 (1952).

Sinitsyn, V. V. andG. V. Vinogradov, Dokl. Akad. Nauk SSSR91, 323 (1953).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Vinogradov, G.V., Ivanova, L.I. Viscous properties of polymer melts and elastomers exemplified by ethylene-propylene copolymer. Rheol Acta 6, 209–222 (1967). https://doi.org/10.1007/BF01976438

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF01976438