Abstract

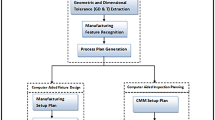

Fixtures are used in many manufacturing operations. Owing to the great variety of parts and manufacturing operations, parts may have different sets of fixturing requirements and call for different design strategies. Although there are numerous possibilities for fixture designs, a few basic configurations are clearly identifiable. Based on the belief that it would be more promising to develop one design strategy for each type of fixture than to attempt to develop a general strategy for all types of fixtures, a three-stage design process has been proposed for automatic design of fixtures: conceptual, configuration, and detail design. This paper focuses on the conceptual design stage. A methodology is presented by which the part shape, part features, and cutting force field are analysed to generate conceptual designs of fixtures.

Similar content being viewed by others

References

H. Asada and M. Kitagawa, “Form closure grasping by a reconfigurable universal gripper”,Proceedings of Manufacturing International, pp. 85–90, 1988.

John J. Bausch and Youcef-Toumi Kamal, “Kinematic methods for automatic fixture reconfiguration planning”,Proceedings of Robotics and Automation, IEEE, pp. 1396–1401, 1990.

B. Bidanda and P. H. Cohen, “Development of a computer aided fixture selection system for concentric, rotational parts”,Symposium on Advances in Integrated Product Design and Manufacturing, ASME Winter Annual Meeting, Dallas, TX, pp. 219–226, November 1990.

J. R. Boerma and H. J. J. Kals, “FIXES, a system for automatic selection of set-ups and design of fixtures”,CIRP, pp. 443–446, 1988.

Yon-Chun Chou, “A methodology for automatic layout of fixture elements based on machining forces considerations”,Symposium on Advances in Integrated Product Design and Manufacturing, ASME Winter Annual Meeting, Dallas, TX, pp. 181–189, November 1990.

Yon-Chun Chou and Moshe M. Barash, “Automatic configuration of machining fixtures: object constraint reasoning”,Proceedings of Manufacturing International, 1990.

Yon-Chun Chou, “A theoretical framework for automatic layout of machining fixtures”, to appear inJournal of Artificial Intelligence for Engineering Design, Analysis and Manufacturing.

A. R. Darvishi and K. F. Gill, “Knowledge representation database for the development of a fixture design expert system”,Proceedings of the Insitution of Mechanical Engineers, Vol. 202, No. B1, pp. 37–49, 1988.

S. J. Gordon and W. P. Seering, “Reconfigurable assembly fixtures”,Proceedings of Manufacturing International, pp. 91–96, 1988.

F. B. Hazen and P. K. Wright, “Workholding automation: innovations in analysis, design, and planning”,Manufacturing Review,3(4), pp. 224–237, 1990.

W. Jiang, Z. Wang and Y. Cai, “Computer-aided group fixture design”,CIRP, pp. 145–148, 1988.

M. Mani and W. R. D. Wilson, “Automated design of workholding fixtures using kinematic constraint synthesis”,Proceedings of North American Manufacturing Research Conference, pp. 437–444, 1988.

A. Markus, “Strategies for the automated generation of modular fixtures”,Proceedings of Manufacturing International, pp. 97–103, 1988.

R. J. Menassa and W. R. DeVries, “A design synthesis and optimization method for fixtures with compliant element”,Symposium on Advances in Integrated Product Design and Manufacturing, ASME Winter Annual Meeting, Dallas, TX, pp. 203–218, November 1990.

D. T. Pham, M. J. Nategh and A. de Sam Lazoro, “A knowledgebased jig and fixture designers' assistant”,International Journal of Advanced Manufacturing Technology,4, pp. 26–45, 1989.

R. H. Sturges. “Toward a rational workholding methodology”,Proceedings of Robotics and Automation, IEEE, pp. 1738–1743, 1990.

J. C. A. Trappey and C. R. Liu, “Automatic generation of configuration for fixturing an arbitrary workpiece using projective spatial occupancy enumeration approach”,Symposium on Advances in Integrated Product Design and Manufacturing, ASME Winter Annual Meeting, Dallas, TX, pp. 191–202, November 1990.

S. Finger and J. R. Dixon, “A review of research in mechanical engineering design. Part I: descriptive, prescriptive, and computerbased models of design processes”,Research in Engineering Design,1, pp. 51–67, 1989.

F. Reuleaux,Kinematics of Machinery, Macmillan, London, pp. 98–114, 1876.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Chou, YC., Srinivas, R.A. & Saraf, S. Automatic design of machining fixtures: Conceptual design. Int J Adv Manuf Technol 9, 3–12 (1994). https://doi.org/10.1007/BF01792862

Issue Date:

DOI: https://doi.org/10.1007/BF01792862