Abstract

Accurate product cost estimation is important in decisions which involved the selection of the least-cost design among alternative designs and the economic feasibility of a product. An accurate cost-estimating procedure would include the cost of materials and all activities that incur cost.

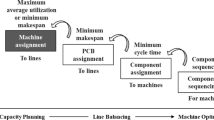

This paper presents the development of cost models for printed circuit board (PCB) assembly which will take into consideration activities that incur cost owing to complexity, volume and batch size of PCB manufactured. All activities are allocated into three level bases and they are unit-level cost, batch-level cost and product-level cost. The cost of assembling one PCB is the summation of all these three costs. A case example is presented to illustrate the application of the models developed.

Similar content being viewed by others

References

G. Boothroyd, “Design for assembly — the key to design for manufacture”,International Journal of Advanced Manufacturing Technology,2(3), pp. 3–11, 1987.

P. J. Sackett and A. E. K. Holbrook, “DFA as a primary process decreases design deficiencies”,Assembly Automation,8(3), pp. 137–140, 1988.

A. J. Allen and K. G. Swift, “Manufacturing process selection and costing”,Proceedings of the Institution of Mechanical Engineers,204(B2), pp. 143–148, 1990.

A. J. Scarr, “Product design for automated manufacture and assembly”,Annals of the CIRP,35(1), pp. 1–5, 1986.

B. Branan, “Instilling a design for assembly culture”. Proceedings, Third International Conference on Product Design for Manufacture and Assembly, Newport, Rhode Island, June 1988.

M. Miyakawa and T. Ohashi, “The Hitachi assemblability evaluation method”, Proceedings, First International Conference on Product Design for Assembly, Newport, Rhode Island, pp. 1–13, June 1986.

G. Boothroyd and P. Dewhurst,Product Design for Assembly Handbook, Boothroyd Dewhurst Inc., Wakefield, Rhode Island, 1989.

G. A. Russell, “Design for assembly of printed circuit board”, Proceedings, First International Conference on Product Design for Assembly, Newport, Rhode Island, June 1986.

R. Cooper, “Implementing an activity-based cost system”,Journal of Cost Management,4(1), pp. 33–42, 1990.

G. J. Beaujon and V. R. Singhal, “Understanding the activity cost in an activity-based cost system”,Journal of Cost Management,4(1), pp. 51–72, 1990.

R. S. Kaplan, “Measuring manufacturing performance: A new challenge for managerial accounting research”,The Accounting Review,58(4), pp. 686–705, 1983.

R. Cooper, “Cost classification in unit-based and activity-based manufacturing cost systems”,Journal of Cost Management,4(3), pp. 4–14, 1990.

BS 621: Part 20: 1984:Guide for the Assembly of Printed Wiring Boards, British Standards Institution, London.

P. J. W. Noble,Printed Circuit Board Assembly, Open University Press, Milton Keynes, U.K., 1989.

A. Kochan (ed.), “Robotics PCB assembly”,Assembly Automation,10(3), pp. 135–137, 1990.

J. Gann and T. Stiles, “Robotic assembly for PCB”,SME Technical paper MS 87-183, Dearborn, Michigan, 1987.

A. Ioannou, “Robotic assembly of PCB”,SME Technical paper MS 86-156, Dearborn, Michigan, 1986.

L. C. Seifert, “Design and analysis of integrated electronics manufacturing systems”, in D. Compton (ed.)Design and Analysis of Integrated Manufacturing Systems, National Academic Press, Washington, pp. 12–33, 1988.

J. F. McKirachan and H. P. Bao, “Producibility considerations for SMT printed circuit card assembly”, Proceedings, Third International Conference on Product Design for Manufacture and Assembly, Newport, Rhode Island, June 1988.

BS 6001: Part 1: 1989Specification for Sampling Plans Indexed by Acceptance Quality Level (AQL) for Lot-by-Lot Inspection, British Standards Institution, London.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Ong, N.S., Lim, L.E.N. Activity-based cost-modelling procedures for PCB assembly. Int J Adv Manuf Technol 8, 396–406 (1993). https://doi.org/10.1007/BF01751101

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF01751101