Abstract

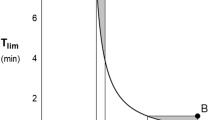

The optimal level to which the mean of a critical variable should be set-up, and the optimal number of repetitions until recalibration, has been jointly determined for the case where the variable is distributed normally and the mean changes linearly with the number of repetitions. It was proven that the optimal set-up level should be below the midpoint between the specification limits by a distance which depends on the slope of change of the mean and on the recalibration cycle, in such a manner that just prior to the recalibration the mean reaches the same distance above the midpoint. A method has been outlined for the numerical evaluation of the optimal number of cycle repetitions, and a general approximation formula was derived, which allows its closed-loop determination. A numerical example and sensitivity analysis are provided.

Similar content being viewed by others

References

A. J. Duncan, “The economic design ofX charts used to maintain current control of a process”,Journal of the American Statistical Association,51, pp. 228–242, 1956

S. P. Ladany, “Optimal use of control charts for controlling current production”,Management Science, Theory,19(7), pp. 763–772, March 1973.

S. P. Ladany and D. N. Bedi, “Selection, of the optimal set-up policy”,Naval Logistics Quarterly,23(2), pp. 219–233, June 1976.

S. P. Ladany and T. Raz, “Optimal dynamic application of a fraction-defective control-chart to control a production process”, in H.-J. Lenz, G. B. Wetherill and P.-Th Wilrich (ed.),Frontiers in Statistical Quality Control 4, Physica-Verlag, Heidelberg, pp. 169–174, 1992.

R. I. Hall and S. Eilon, “Controlling production processes which are subject to linear trends”,Operational research quarterly,14(3), pp. 279–289 1963.

S. Eilon, R. I. Hall, and J. R. King,Exercises in Industrial Management, pp. 123–131, Macmillan, London, 1966.

Z. S. Roth, B. W., Mooring and B. Ravani, “An overview of robot calibration”,IEEE Journal of Robotics and Automation,3(5), pp. 377–385, 1987.

J. Chen and L. M. Chao, “Positioning error analysis for robot manipulators with all rotary joints”,IEEE Journal of Robotics and Automation,3(6), pp. 539–545, 1987.

F. Azadivar, “The effect of joint position errors of industrial robots on their performance in manufacturing operation”,IEEE Journal of Robotics and Automation,3(2), pp. 109–114, 1987.

P. M. Morse,Queues, Inventories and Maintenance, ORSA Publication No. 1, John Wiley, New York, 1958.

B. Lambert, A. Walvekar and J. Hirmas, “Optimal redundancy and availability allocation in multistage systems”,IEEE Transactions on Reliability,26(3), pp. 182–185, 1971.

S. G. Tzafestas, “Optimization of systems reliability: a survey of problems and techniques”,International Journal of Systems Science,11(4), pp. 55–86, 1980.

K. Nakashima and K. Yamato, “Optimal design of a series parallel systems with time dependent reliability”,IEEE Transactions on Reliability,26(2), pp. 119–129, 1977.

S. P. Ladany and D. Ben-Arieh, “Optimal industrial robotcalibration policy”,The International Journal of Advanced Manufacturing Technology,5, pp. 345–357, 1990.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Ladany, S.P. Optimal combined set-up and calibration policy. Int J Adv Manuf Technol 9, 134–140 (1994). https://doi.org/10.1007/BF01750420

Issue Date:

DOI: https://doi.org/10.1007/BF01750420