Abstract

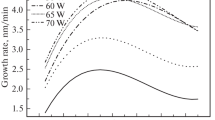

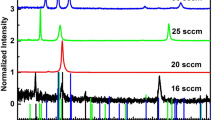

The electrical resistivity of as deposited polycrystalline copper thin films as a function of varying the process parameters has been investigated. Trying to minimize the resistivity of the copper thin films is important in the semiconductor industry, due to the fact that low resistivity copper can be employed to great advantage for new metallization schemes in advanced ultralarge scale integrated circuits. This paper presents the optimum choice of parameters that are necessary to achieve low resistivities of the thin films in reproducible experiments. All the depositions were performed using an unbalanced d.c. planar magnetron sputtering source (consisting of a circular copper target (98% purity, 0.01% Fe, 0.005% Ni, 0.005% Si) with a diameter of 100mm fitted with two electromagnets). The copper thin films were deposited onto glass substrates with argon being used as the sputtering gas. The resistivity was studied as a function of the pressure of the sputtering gas, the substrate bias, the substrate to target distance, the magnetron power, and the substrate temperature. It was found that depositions producing thin films with a resistivity of that approaching the bulk material (1.7×10−8Ωm) were obtained if the sputtering gas pressure was below 0.2 Pa. The effect of the substrate bias was insignificant at these pressures. The crystallographic structure of the copper thin films, determined by X-ray diffraction, is also reported.

Similar content being viewed by others

References

Craig S. and Harding G. L.: J. Vac. Sci. Technol.19 (1981) 205.

Monaghan D. and Arnell R. D.: Surface and Coatings Technology49 (1991) 298.

Fountzoulas C. and Nowak W. B.: J. Vac. Sci. Technol. A9 (1991) 2128.

Bai P., McDonald J. F., and Lu T.-M.: J. Vac. Sci. Technol. A9 (1991) 2113.

Roy R. A., Cuomo J. J., and Lee D. S.: J. Vac. Sci. Technol. A6 (1988) 156.

Roy R. A., Cuomo J. J., and Lee D. S.:in Mat. Res. Soc. Symp. Proc., Vol. 128, 1989, p. 23.

Moss R. W. and Mertz M. D.: J. Vac. Sci. Technol. A3 (1985) 2694.

Burnett A. F. and Cech J. M.: J. Vac. Sci. Technol. A11 (1993) 2970.

Ueda H., Kitakami O., Shimada Y., Igari Y., and Kusunoki I.: Jpn. J. Appl. Phys.33 (1994) 2015.

Ohmi T. and Shibata T.: Thin Solid Films241 (1993).

Turner G. M., Rossnagel S. M., and Cuomo J. J.: J. Vac. Sci. Technol. A11 (1993) 2796.

Asamaki T., Mori R., and Takagi A.: Jpn. J. Appl. Phys.33 (1994), Pt. 1, No. 5A, 2500.

Escrivao M. L., Moutinho A. M. C., and Maneira M. J. P.: J. Vac. Soc. Tech. A12 (1994) 723.

Maissel L. I. and Schaible P. M.: J. Appl. Phys.36 (1965) 237.

Nitta T., Ohmi T., Otsuki M., Takewaki T., and Shibata T.: J. Electrochem. Soc.139 (1992) 922.

Author information

Authors and Affiliations

Additional information

The authors would like to thank Dr. Soukup for his support during this research. We would also like to express our gratitude to Mr. A. Rajský for improving the design of the sputtering device. This work was partially financed by a grant from the Grant Agency of the Czech Republic No. 202/93/0508.

Rights and permissions

About this article

Cite this article

Musil, J., Bell, A.J. & Čepera, M. Deposition of copper films by unbalanced d.c. magnetron sputtering. Czech J Phys 45, 249–261 (1995). https://doi.org/10.1007/BF01700266

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF01700266