Summary

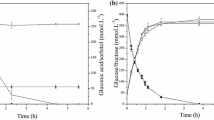

This article deals with continuous hydrolysis of acrylamide into acrylic acid using the wild-typeBrevibacterium sp. R312 which can hydrolyze all water-soluble amides into their corresponding acids. Biotransformation has been carried out in a fluidized bed reactor specially designed to obtain good contact conditions between cells entrapped into small calcium alginate beads (2–3 mm) and low-concentration acrylamide solutions (10–40g·l−1). Different flow rates, biocatalyst loads and substrate concentrations have been investigated. Kinetic constants for the immobilized enzyme have been identified. It appears that the Michaelis constant does not change with operating conditions and remains roughly equal to the value obtained for free cells. In contrast, the maximum rate of hydrolysis is considerably decreased, as if only cells on the outskirts of beads were involved in the transformation. On the whole it is proved that corynebacteria cells could be usefully used for the bioconversion of amides in a continuous immobilized cell reactor; the higher the solid hold-up and/or the smaller the beads, the more efficient the biological transformation.

Similar content being viewed by others

References

Arnaud, A., P. Galzy and J.C. Jallageas. 1976. Remarques sur l'activité nitrilasique de quelques bactéries. C.R. Acad. Sci. Paris 283: 571–573.

Arnaud, A., P. Galzy and J.C. Jallageas. 1976. Etude del'activité nitrilasique de quelques bactéries. Rev. Ferment. Ind. aliment. 31: 39–44.

Arnaud, A., P. Galzy and J.C. Jallageas. 1976. Amidase activity of some bacteria. Folia Microbiol. 21: 178–184.

Arnaud, A., J.C. Jallageas and P. Galzy. 1977. Etude de l'acétonitrilase d'une souche deBrevibacterium. Agric. Biol. Chem. 41: 2183–2191.

Asano, Y., K. Fujishiro, Y. Tani and H. Yamada. 1982. Aliphatic nitrile hydratase fromArthrobacter, sp. J-1. Purification and characterization. Agric. Biol. Chem. 46: 1165–1174.

Asano, Y., M. Tachibana, Y. Tani and H. Yamada. 1982. Purification and characterization of an amidase which participates in nitrile degradation. Agric. Biol. Chem. 46: 1175–1181.

Asano, Y., T. Yasuda, Y. Tani and H. Yamada. 1982. A new enzymatic method of acrylamide production. Agric. Biol. Chem. 46: 1183–1189.

Brown, P.R., M.J. Smyth, P.H. Clarke and M.A. Rosemeyer. 1973. The sub-unit structure of the aliphatic amidase fromPseudomonas aeruginosa. Eur. J. Biochem. 34: 177–187.

Bui, K., A. Arnaud and P. Galzy. 1982. A new method to prepare amides by bioconversion of corresponding nitriles. Enzyme Microb. Technol. 4: 195–197.

Bui, K., H. Fradet, A. Arnaud and P. Galzy. 1984. A nitrile hydratase with a wide substrate spectrum produced by aBrevibacterium sp. J. Gen. Microbiol. 130: 89–93.

Bui, K., H. Fradet, A. Thiéry, M. Maestracci, A. Arnaud and P. Galzy. 1984. Use of nuclear magnetic resonance and gas-liquid chromatography for the study of microbial nitrile-hydratases and amidases. Anal. Chim. Acta 163: 315–322.

Bui, K., M. Maestracci, A. Thiéry, A. Arnaud and P. Galzy. 1984. A note on the enzymic action and biosynthesis of a nitrile hydratase from aBrevibacterium sp. J. Appl. Bacteriol. 57: 183–190.

Clarke, P.H. 1970. The aliphatic amidases ofPseudomonas aeruginosa. Adv. Microbiol. Physiol. 4: 179–222.

Clarke, P.H. 1972. Biochemical and immunological comparison of aliphatic amidases produced byPseudomons sp. J. Gen. Microbiol. 71: 241–257.

Clarke, P.H. 1974. Amidases ofPseudomonas species. Biochem. Soc. Trans. 2: 831–834.

Clarke, P.H., M.A. Houldsworth and M.D. Lilly. 1968. Catabolism repression and the induction of amidase synthesis byPseudomonas aeruginosa 8602 in continuous culture. J. Gen. Microbiol. 51: 225–234.

Fradet, H., A. Arnaud, G. Rios and P. Galzy. 1985. Hydratation of nitriles using a bacterial nitrile hydratase immobilized on DEAE-cellulose. Biotechnol. Bioeng. 27: 1581–1585.

Galzy, P., A. Arnaud, A. Commeyras and J.C. Jallageas. 1974. Procédé de préparation d'amides par hydrolyse biologique. French Patent No. 74,41828.

Hynes, M.J. 1970. Induction and repression of amidase enzyme inAspergillus nidulans. J. Bacteriol. 103: 482–487.

Hynes, M.J. 1975. Amide utilization inAspergillus nidulans. Evidence for a third amidase enzyme. J. Gen. Microbiol. 91: 99–109.

Hynes, M.J. and J.A. Pateman. 1970. The use of amides as nitrogen sources byAspergillus nidulans. J. Gen. Microbiol. 63: 317–324.

Hynes, M.J. and J.A. Pateman. 1970. The genetic analysis of regulation of amidase synthesis inAspergillus nidulans. I. Mutants able to utilize acrylamide. Mol. Gen. Genet. 108: 79–106.

Hynes, M.J. and J.A. Pateman. 1970. The genetic analysis of regulation of amidase synthesis inAspergillus nidulans. II. Mutants resistant to fluoroacetamide. Mol. Gen. Genet. 108: 107–116.

Jallageas, J.C., A. Arnaud and P. Galzy. 1978. Etude de l'acétamidase d'une souche deBrevibacterium. J. Gen. Appl. Microbiol. 24: 103–114.

Jallageas, J.C., A. Arnaud and P. Galzy. 1978. Application de la chromatographie en phase gazeuse á l'étude des nitrilases et amidases. J. Chromatogr. 166: 181–187.

Jallageas, J.C., A. Arnaud and P. Galzy. 1980. Bioconversion of nitriles and their applications. Adv. Biochem. Eng. 14: 1–32.

Levenspiel, O. 1979. Enzyme fermentation. In: The Chemical Reactor Omnibook. Ch. 81 OSU Book Stores. Corvallis, OR, U.S.A.

Maestracci, M., K. Bui, A. Thiéry, A. Arnaud and P. Galzy. 1984. A study of the inhibition of an amidase with a wide substrate spectrum and its consequences for the bioconversion of nitriles. Biotechnol. Lett. 6: 149–154.

Maestracci, M., A. Thiéry, A. Arnaud and P. Galzy. 1986. A study of the mechanism of the reaction catabolized by the amidase ofBrevibacterium sp. R. 312. Agric. Biol. Chem. 50: 2237–2241.

Maestracci, M., A. Thiéry, K. Bui, A. Arnaud and P. Galzy. 1984. Activity and regulation of an amidase (acylamide amidohydrolase E.C.3.5.1.4.) with a wide substrate spectrum from aBrevibacterium sp. Arch. Microbiol. 138: 315–320.

Matsuda, F. and N. Hashimoto. 1976. Acrylamide par hydratation catalytique directe. Inf. Chim. 160: 223–227.

Miller, J.M. and C.J. Knowles. 1984. The cellular location of nitrilase and amidase enzymes ofBrevibacterium sp. R 312. FEMS Microbiol. Lett. 21: 147–151.

Nitto Chemical Industry Co, Ltd. 1979. Procédé de préparation de l'acrylamide et du méthacrylamide à l'aide de microorganismes. French Patent No. 79, 07935.

Papaconstantinou, S., S. Elmaleh and G.M. Rios. 1986. Hydrodynamics and mass transfer in a high compacting multiphasic reactor. In: Heat and Mass Transfer in Fixed and Fluidized Beds. (Van Swaaij, W.P.M. and N.H. Afgan, eds.), pp. 711–718, Hemisphere Publication Corp., Washington, New York and London.

Rios, G.N., J.L. Baxerres and H. Gibert. 1979. Procédé de mise en contact d'une phase gazeuse, d'au moins une phase liquide et d'au moins une phase solide à l'état divisé. French Patent No. 79, 17430.

Svensson, B. and M. Ottensen. 1981. Entrapment of chemical derivates of glyco-amylase in calcium alginate gels. Carlsberg Res. Commun. 46: 13–24.

Thiéry, A., M. Maestracci A. Arnaud and P. Galzy. 1985. Induction de l'amidase d'une souche deBrevibacterium sp. Structure chimique de l'inducteur. Belgian J. Food Chem. Biotechnol. 40: 115–117.

Thiéry, A., M. Maestracci, A. Arnaud and P. Galzy. 1985. Acyltransferase activity of the wide spectrum amidase ofBrevibacterium sp. J. Gen. Microbiol. 132: 2205–2208.

Thiéry, A., M. Maestracci, A. Arnaud, P. Galzy and M. Nicolas. 1986. Purification and properties of an acylamide amidohydrolase (E.C.3.5.1.4.) with a wide activity spectrum fromBrevibacterium sp. R 312. J. Basic. Microbiol. 26: 299–311.

Tourneix, D., A. Thiéry, M. Maestracci, A. Arnoud and P. Galzy. 1986. Regulation of nitrile hydratase synthesis in aBrevibacterium species. Antonie Van Leeuwenhoek 52: 173–182.

Watanabe, I., K. Sakashita and Y. Ogawa. 1981. Procédé de préparation de l'acrylamide à l'aide de cellules immobilisées d'un type nouveau. French Patent No. 81, 15932.

Watanabe, I. and Y. Satoh. 1980. Procédé pour préparer une solution aqueuse stable d'acrylamide ou de méthacrylamide à l'aide de microorganismes. French Patent No. 80, 03188.

Watanabe, I., Y. Satoh and T. Takano. 1979. Acrylamide and methacrylamide produced using microorganisms. Ger. Offen. 2,912,292.

Yamaguchi, Y., I. Watanabe and Y. Satoh. 1980. Procédé microbiologique pour la production d'une solution aqueuse d'acrylamide fortement concentrée. French Patent No. 80, 13635.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Bernet, N., Thiéry, A., Maestracci, M. et al. Continuous immobilized cell reactor for amide hydrolysis. Journal of Industrial Microbiology 2, 129–136 (1987). https://doi.org/10.1007/BF01569419

Received:

Revised:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF01569419