Conclusions

-

1.

Any composition of poured and plastic asphalt material (asphaltic concrete, asphalt grout, asphalt binder) is pressed into cracks of a rock foundation, if it contains particles with a size less than the crack width and if the content of bitumen in it exceeds by not less than -3% the volume of voids of its mineral part in a consolidated state.

-

2.

The rate of pressing the asphalt into the crack decreases with time and stops completely: when the source of the crack is bridged by an arch of large fractions exceeding the crack width in size; when the content in the interlayer asphalt of particles exceeding the arch-forming particles in size approaches 100%; when the composition of asphalt in the region of the crack approaches the composition being compacted (Bex≤−3%) with a yield stress under compression approaching the value of the compressive stress acting in the region of the crack; when the resistance of the asphalt to pressure in the crack is balanced by the pressing force acting in the crack.

-

3.

The design characteristics of the asphalt material whose depth of penetration into the crack is being determined should be found for a composition of the asphalt material of the interlayer after screening from its mineral part fractions with a size exceeding the width of the crack under consideration.

-

4.

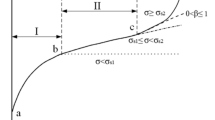

The maximum depth of penetration of poured asphalt into a plane crack in the rock foundation of an earth dam can be determined reliably by relation (11), and in the case of making the interlayer in the dam foundation from hot poured asphalt grout with composition 90∶10∶20 with a consistency of 2.6–3.2 sec at 150°C, by the graph in Fig. 3.

-

5.

In the case of making the asphalt interlayer in the dam base from hot poured asphalt grout, all cracks in its rock foundation are inevitably plugged, with the course of time, to a depth of 0.4–0.5 m (depending on the crack width, composition and properties of the asphalt in the interlayer, and compressive forces acting in it).

Similar content being viewed by others

Literature cited

Yu. N. Kasatkin, M. Pavchich, and V. G. Radchenko, “Use of asphalt material for joining earth dams,” Gidrotekh. Stroit., No. 2 (1989).

Recommendations on the Design of Graded Filters of Hydraulic Structures, P 92–80 [in Russian], VNIIG, Leningrad (1981).

Yu. I. Kasatkin, “Characteristics of the interaction of asphaltic concrete of a diaphragm with earth of the dam body,” Izv. VNIIG im. B. E. Vedeneeva,149 (1981).

Substantiation of the Design Parameters for Nonrigid Pavements [in Russian], Dorizdat, Moscow (1952).

I. I. Kandaurov, Mechanics of Granular Media and Their Use in Constructions [in Russian], Stroiizdat, Leningrad-Moscow (1966).

Additional information

Translated from Gidrotekhnicheskoe Stroitel'stvo, No. 6, pp. 30–33, June, 1992.

Rights and permissions

About this article

Cite this article

Kasatkin, Y.N., Omarov, G.A., Pavchich, M. et al. Determination of the regime of plugging cracks in the rock foundation of an earth dam. Hydrotechnical Construction 26, 353–358 (1992). https://doi.org/10.1007/BF01545617

Issue Date:

DOI: https://doi.org/10.1007/BF01545617