Conclusions

-

1.

The types of failures experienced by knitting-machine needles are ascertained and it is established that breakdown of the hook is primary among these failures.

-

2.

Ilook failure is fatigue in nature, while heel failure is quasistatic owing to repeated or one-time overloading.

-

3.

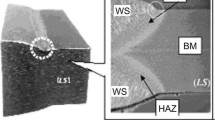

The point of crack initiation, which is located on the inside of the hook at the starting point of its bend, is detected.

-

4.

The microstructure of needles with different service lives is investigated, and the instability of the physicomechanical properties of the material from which the needle is fabricated is ascertained.

-

5.

The following measures can be recommended to increase needle longevity: analysis of sources of random overloads, and their reduction for complete elimination; exclusion of production operations that give rise to the application of transverse scratches and striations during needle fabrication, especially in the bend region of the hook on the inside; and ascertaining and eliminating sources of instability in the physicomechanical properties of the needle material.

Similar content being viewed by others

Literature Cited

V. P. Voloshchenko, B. F. Pipa, and S. T. Shipukov, Operational Reliability of Machinery Used in Knitted-fabric Production [in Russian], Tekhnika, Kiev (1977).

M. N. Stepanov, Statistical Processing of Mechanical Test Results [in Russian], Mashinostroenie, Moscow (1972).

P. J. E. Forsyth, “Fatigue damage and crack growth in aluminum alloys”, Acta Met., No. 11, 703–715 (1963).

C. Laird, “The influence of metallurgical structure on the mechanisms of fatigue crack propagation”, in: Fatigue Crack Propagation, Philadelphia (1967), pp. 131–168.

D. Broek, “Some contributions of electron fractography to the theory of fracture”, Int. Met. Rev.,19, 135–182 (1974).

L. R. Botvina, “Fatigue-failure criterion characterizing the start of developed plastic flow at the crack tip”, in: Cyclic Fracture Toughness of Metals and Alloys [in Russian], Nauka, Moscow (1981), pp. 53–59.

K. D. Beacham, “Fracture microprocesses”, in: Fracture [Russian translation], Vol. 1, Mir, Moscow (1973), pp. 265–374.

Additional information

Institute of Strength Problems, Academy of Sciences of the Ukrainian SSR, Kiev. Translated from Problemy Prochnosti, No. 7, pp. 68–71, July, 1983.

Rights and permissions

About this article

Cite this article

Krasovskii, A.Y., Kramarenko, I.V. & Gaidamaka, V.G. Character and causes of in-service needle failure in knitting machines. Strength Mater 15, 969–972 (1983). https://doi.org/10.1007/BF01528942

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF01528942