Conclusions

-

1.

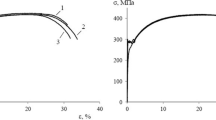

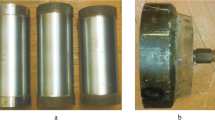

The nature of the failure and the value of the limit stress amplitude for tubular specimens made from straight pipes differ from those for specimens made of bent pipes. The propagation of the longitudinal fatigue crack in tubular specimens made from bent pipes concludes with its unstable growth, and the fatigue limit of these specimens in a pulsating cycle is 27% lower than of specimens made from straight pipes. Consequently, the technology adopted for producing the bent pipes impairs the fatigue strength and the resistance to brittle failure.

-

2.

The influence coefficient of cycle asymmetry for pipes loaded by internal pressure differs from a similar coefficient in uniaxial tests of standard specimens. On the section from the symmetric to the pulsating cycle, the influence coefficient of asymmetry in the loading of pipes is approximately 0.375. When the coefficient of asymmetry and the mean stress rise further, the influence coefficient of asymmetry decreases, according to the results of the executed experiment it is equal to 0.164.

-

3.

On the basis of the generalization of the known expressions and the obtained experimental data a dependence was suggested for the approximate engineering evaluation of the limit amplitude of the cycle for straight pipes made of low alloy medium-strength steels.

-

4.

The value of the influence coefficient of cycle asymmetry found and the dependence for calculating the limit amplitude of the cycle obtained with its aid make it possible to increase by 13–15% the accuracy of stress analysis of pipes (cylinders) for obtaining the practical coefficients of asymmetry and the mean stresses induced by variable internal pressure. With increasing mean stresses the accuracy of the calculations increases.

Similar content being viewed by others

Literature Cited

Ya. Kh. Faupel, “Stress analysis of pressure vessels,” in: The Design and Production Technology of Pressure Vessels [in Russiann] Mashinostroenie, Moscow (1975), pp. 330–384.

M. Nisihara, E. Yamaguti, and S. Hattori, “Fatigue strength calculation of thick-walled ultrahigh-pressure cylinders,” Acurioku Gidzyucu,13, No. 1, 2–8 (1975).

E. Yamaguti, S. Hattori, and Ch. Yanai, “Nikhon Kikai Gakkai Rombunsyu,42, No. 353, 8–15 (1976).

B. Crossland, “The effect of pressure on the fatigue of metals,” in: The Mechanical Properties of Materials under High Pressure [Russian translation], Mir, Moscow (1973), pp. 152–212.

V. P. Kogaev, Stress Analysis with Time-Variable Stresses [in Russian], Mashinostroenie, Moscow (1977).

H. Ford, K. E. Bett, T. Rogan, and N. F. Cardner, “Design criteria for pressure vessels,” Chem. Eng. Progress,68, No. 11, 77–79 (1972).

A. F. Berman, E. R. Khismatulin, and E. Ya. Neiman, “The reliability of pipes and tubular apparatuses of installations for the production of polyethylene,” Khim. Neft. Mashinostr., No. 2, 24–26 (1983).

A. F. Berman and L. N. Kolosova, “Analysis of breakdowns of pipe and pipeline components of installations for producing polyethylene under high pressure,” in: Reliability and Safety in the Production of Polyethylene under High Pressure, A. G. Platonov (ed.), ONPO “Plastpolimer,” Leningrad (1983), pp. 60–71.

GOST 19533-74. Reliability of Engineering Products. Accelerated Evaluation of Fatigue Limits by the Method of Stepped Loading (Lokati): Instead of-For the First Time. Introduced January 1, 1975.

J. L. M. Morrison, B. Crossland, and J. S. C. Parry, “Strength of thick cylinder subjected to repeated internal pressure,” Proc. Inst. Mech. Eng.,174 No. 2, 95–117 (1960).

Additional information

Irkutsk Research and Design Institute of Chemical Machinery, Irkutsk Translated from Problemy Prochnosti, No. 8, pp. 81–86, August, 1986.

Rights and permissions

About this article

Cite this article

Berman, A.F., Kolosova, L.N. Experimental investigation of the strength of pipes loaded by variable internal pressure. Strength Mater 18, 1088–1093 (1986). https://doi.org/10.1007/BF01525359

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF01525359