Conclusions

-

1.

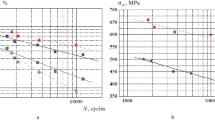

For 15Kh2MFA(II) steels in the failure of which in specimens from 25- to 150-mm-thick plane strain conditions are maintained, the specimen thickness does not influence the fatigue crack growth rate and the characteristics Kth and Kfc.

-

2.

For the plastic steels 15Kh2NMFA, 15Kh2MFA(I), and 08Kh18N10T, the fatigue failure of which is accompanied by the development of significant plastic deformations at the crack tip the influence of specimen thickness on the rules of fatigue crack growth is ambiguous in the case of presentation of the experimental data to da/dN−KImax coordinates and may appear in the whole range of change in KImax from Kth to K fQ .

-

3.

Among the parameters of nonlinear fracture mechanics (J-integral, KIe, δ 0.1max ) investigated using as an example their use as characteristics determining the fatigue crack growth rate in specimens of different thickness of 15Kh2MFA(I) and 15Kh2NMFA steels only the crack tip opening δ 0.1max unambiguously determines the fatigue crack growth rate in the high-amplitude area.

Similar content being viewed by others

Literature Cited

S. P. Malashenkov, A. G. Vovnyanko, and G. Yu. Bengus, “The influence of specimen width and thickness on the fracture toughness and parameters of the fatigue failure curve of aluminum alloy semifinished products,” in: The Crack Resistance of Materials and Structural Elements [in Russian], Naukova Dumka, Kiev (1980), pp. 269–273.

V. N. Simin'kovich, Ya. N. Gladkii, and N. A. Deev, “The construction of kinetic fatigue curves from the results of tests on a machine with rigid loading of specimens of different thickness,” in: Methods and Means of Evaluation of the Crack Resistance of Constructional Materials [in Russian], Naukova Dumka, Kiev (1981), pp. 228–231.

V. I. Trufyakov, P. P. Mikheev, and A. Z. Kuz'menko, “The influence of the scale factor and residual welding stresses on the fatigue crack propagation rate,” Probl. Prochn., No. 6, 20–22 (1980).

F. A. Heiser and W. Mortimer, “Effect of thickness and orientation on fatigue crack growth rate in 4340 steel,” Met. Trans.,3, No. 8, 2119–2123 (1972).

P. N. Thielen and E. F. Morris, “Fatigue crack propagation, in 4140 steel,” Met. Trans., A,6, No. 11, 2133–2141 (1975).

D. P. Wilhem, “Investigation of cyclic crack growth transitional behavior,” in: Fatigue Crack Propagation. ASTM Spec. Tech. Publ. No. 415, Philadelphia (1967), pp. 363–383.

M. N. Georgiev, V. Yu. Dogadushkin, N. Ya. Mezhova, et al., “The relationship of fatigue crack growth rate in St. 3sp to the dimensions and orientation of the specimen,” Fiz.-Khim. Mekh. Mater.,17, No. 3, 18–24 (1981).

W. G. Clark and H. E. Trout, “Influence of temperature and section size on fatigue crack growth behavior in Ni-Mo-V alloy steel,” Eng. Fract. Mech.,2, No. 2, 107–123 (1970).

A. R. Jack and A. T. Price, “Effects of thickness on fatigue crack initiation and growth in notched mild steel specimens,” Acta Met.,20, No. 7, 857–866 (1972).

E. Wessel, W. Clark, and W. Prail, “Calculations of steel structures with thick cross sections by fracture mechanics methods,” in: New Methods of Evaluation of the Brittle Fracture Resistance of Metals [Russian translation], Yu. N. Rabotnov (ed.), Mir, Moscow (1974), pp. 213–244.

J. G. Kaufman, R. J. Bucci, and R. A. Kelsey, “Fracture mechanics aspects of the structural integrity technology of spherical aluminum containment vessels for LNG tankers,” Trans. ASME,102, No. 3, 303–314 (1980)

N. L. Person and G. C. Wolfer, “Fatigue crack growth rate of thick 5083-0 plate at room and low temepratures,” in: Properties of Materials for Liquified Natural Gas Tankage, ASTM Spec. Tech. Pub. No. 579, Philadelphia (1975), pp. 80–95.

A. M. Sullivan and T. W. Crooker, “The effect of specimen thickness upon the fatigue crack growth rate of A516-60 pressure vessel steel,” Trans. ASME. J.,99, No. 2, 248–252 (1977).

J. J. McGowan and H. V. Liu, “The role of three-dimensional effects in constant amplitude fatigue crack growth testing,” Trans. ASME. H,102, No. 4, 341–346 (1980).

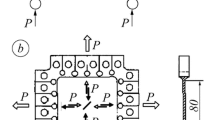

V. T. Troshchenko, V. V. Pokrovskii, V. G. Kaplunenko, et al., “The influence of specimen dimensions on the crack resistance of heat resistant shell steels,” Probl. Prochn., No. 10, 3–11 (1982).

N. A. Makhutov, Deformation Criteria of Failure and Calculation of Structural Elements for Strength [in Russian], Mashinostroenie, Moscow (1981).

Additional information

Institute of Strength Problems, Academy of Sciences of the Ukrainian SSR, Kiev. Translated from Problemy Prochnosti, No. 4, pp. 3–9, April, 1986.

Rights and permissions

About this article

Cite this article

Troshchenko, V.T., Pokrovskii, V.V. & Kaplunenko, V.G. Influence of specimen dimensions on the characteristics of cyclic crack resistance of heat-resistant steels. Report I. Strength Mater 18, 419–425 (1986). https://doi.org/10.1007/BF01524059

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF01524059