Conclusions

-

1.

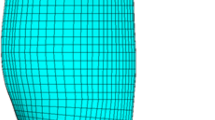

It is necessary to take into account the flexural rigidity of damping wire connectors during blade vibration. Disregarding the flexural rigidity of the wires may lead to significant errors for mainly torsional vibration configurations.

-

2.

Energy disippation in the contact zone between blades and connectors appears to be a governing factor after the dynamic stress level has risen to reach a level corresponding to slip initiation over the whole contact zone. The specified level markedly depends on the construction and number of connectors, and may be altered over a wide range as required.

-

3.

After slip initiation over the whole contact area vibration frequency decreases, with increasing amplitude. For mainly torsional vibration the dynamic stress level in the blades corresponding to slip initiation increases, as a rule, with increasing turbine power.

Similar content being viewed by others

Literature Cited

A. Z. Shemtov and K. N. Borishanskii, “Some vibration features of blade rims in turbomachines with fastening connectors around the wheel,” Probl. Prochn. No. 8, 74–78 (1972).

B. A. Smol'nikov, “Calculation of free vibration in a closed frame system with cyclic asymmetry,” Tr. Leningr. Polytekh. Inst., No. 210, 213–219 (1960).

B. S. Blinnik, V. T. Efremova, and B. F. Shorr, “Calculation of the natural frequency of linked vibrations in shrouded blades,” in: Strength Calculations [in Russian], Vol. 16, Moscow (1975), pp. 240–260.

K. N. Borishanskii, “Energy dissipation during vibration in shrouded blades,” in: Energy Dissipation during Vibration of Mechanical Systems [in Russian], Kiev (1974), pp. 263–272.

K. N. Borishanskii, “Vibration features of shrouded blades,” Probl. Prochn. No. 9, 97–102 (1974).

A. V. Shchelyaev, Steam Turbines [in Russian], Énergiya, Moscow (1976).

S. D. Ponomarev et al., Strength Calculations in Engineering [in Russian], Vol. II, Mashgiz, Moscow (1958).

K. N. Borishanskii, “Comparison of experimental and theoretical results in the study of blade rim vibrations with fastening connectors around the wheel,” Probl. Prochn., No. 8, 79–82 (1972).

I. A. Birger, B. F. Shorr, and R. M. Shneiderovich, Strength Calculation for Machine Parts [in Russian], Mashinostroenie, Moscow (1966).

K. N. Borishanskii, “Energy dissipation during rotor blade vibration in the latter stages of a high power steam turbine,” Probl. Prochn., No. 5, 9–13 (1975).

Additional information

Leningrad. Translated from Problemy Prochnosti, No. 6, pp. 8–13, June, 1978.

Rights and permissions

About this article

Cite this article

Borishanskii, K.N. Vibration features of turbine blades with fastening connectors a round the wheel. Strength Mater 10, 625–630 (1978). https://doi.org/10.1007/BF01523889

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF01523889