Abstract

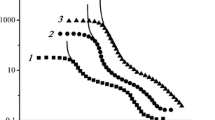

The rheological behaviour of aqueous solutions of two commercial anionic hydrophobically modified alkali-swellable emulsions (HASE), Acrysol TT615 and RM5, was studied. These polymeric systems, initially in the form of low-viscosity latices at low pH, tend to swell and increase their viscosity when neutralised with base. The steady-shear and dynamic properties of these polymers were measured over a wide range of concentration, at constant pH=9 and temperature of 20°C. The intrinsic and zero-shear viscosities were used to identify the concentration regimes of the polymer solutions. In the case of Acrysol TT615, the solution exhibited shear-thinning characteristics at a concentration above 500 ppm. The Carreau model described well the viscosity function of the 1000 and 2000 ppm solutions. Considerable viscosity enhancement and a change in the flow curve profile were observed at concentrations above 2000 ppm. At high polymer concentration. the zero-shear viscosity was not detectable, and the power law model was adequate to characterize these solutions. By contrast, the RM5 solutions exhibited nearly Newtonian behaviour over the whole concentration range considered. Elasticity measured from the first normal stress difference indicated that Acrysol TT615 was more elastic than Acrysol RM5. Dynamic measurements revealed that both storage (G′) and loss (G″) moduli increased with polymer concentration. In the higher frequency and concentration regions, G′ > G″ was obseved for TT615, whereas G″ > G′ for RM5.

Similar content being viewed by others

Abbreviations

- c:

-

concentration; superscript * denotes critical concentration

- G′:

-

storage modulus

- G″:

-

loss modulus

- Je ° :

-

steady state compliance

- k′:

-

Huggins constant

- k″:

-

Kramer constant

- K:

-

constant in Mark- Houwink-Sakurada equation, Eq. (3)

- M:

-

viscosity-average molecular weight

- m:

-

fluid consistency index in the power law viscosity model, Eq. (5)

- m′:

-

consistency index in the power law normal stress model, Eq. (7)

- n:

-

flow behavior index in the power law viscosity model, Eq. (5)

- n′:

-

flow behavior index in the power law normal stress model, Eq. (7)

- N:

-

parameter in the Carreau model equation, Eq. (6)

- N1 :

-

first normal stress difference

- <r2>3/2 :

-

effective volume of the polymer in solution; power 1/2 refers to end-to- end chain length

- tc :

-

Carreau time constant

- α:

-

power in Mark-Houwink-Sakurada equation, Eq. (3)

- γ:

-

shear rate

- η:

-

viscosity; subscript “o” denotes zero-shear, “∞” denotes infinite-shear, “r” denotes relative, “sp” denotes specific viscosity; and [ ] denotes intrinsic viscosity

- λM :

-

Maxwell relaxation time; supercript “o” denotes zero-deformation

- Φ:

-

universal constant in Eq. (4)

- δii :

-

stress components

- ω:

-

frequency

References

S. I. Abdel-Khalik, O. Hassager and R. B. Bird,Polym. Eng. Sci.,14, 859 (1974).

T. Annable, R. Buscall, R. Ettelaie and D. Whittlestone,J. Rheol.,37, 695 (1993).

T. Aubry and M. Moan,J. Rheol.,38, 1681 (1994).

T. Aubry, and M. Moan,J. Rheol.,40, 441 (1996).

M. J. Ballard, R. Buscall and F. A. Waite,Polymer,29, 1287 (1988).

D. V. Boger and H. H. Nguyen,Polym. Eng. Sci.,18, 1037 (1978).

J. Brandrup and E. H. Immergut,Polymer Handbook, Wiley & Sons Inc., N. Y., 1975.

P. J. Carreau,Trans. Soc. Rheol.,16, 99 (1972).

R. Dersch, Surf. Coat. Australia, 18 (May 1994).

S. Evani and G. D. Rose,Proc. ACS Div. Polym. Mater. Sci. Eng. Mtg. Fall,57, 477 (1987).

J. D. Ferry, 3rd Ed., John Willey, N. Y., 1980.

P. J. Flory and T. G. Fox,J. Polym. Sci.,5, 745 (1950).

G. Fonum, J. Bakke and F. K. Hansen,Colloid and Polym. Sci.,271, 380 (1993).

H. Giesekus,Rhea. Acta,6, 339 (1967).

P. R. Howard, E. L. Leasure, S. T. Rosier and E. J. Schaller,J. Coat. Techn.,64(804), 87 (1992).

M. L. Huggins,J. Am. Chem. Soc.,64, 2716 (1942).

R. D. Jenkins, C. A. Silebi and EI-Aasser,ACS. Sym. Ser. 462, 222 (1991).

E. O. Kramer,Ind. Eng. Chem.,30, 1200 (1938).

D. J. Lundberg J. E. Glass,J. Rheol.,35, 1255 (1991).

A. K. Murthy and M. Muthukumar,Macromolecules,20, 564 (1987).

G. Nicolae, Mater. Eng. Sci. Thesis, Monash University (1995).

W. Noll,Arch. Rat. Mech. Anal.,2, 197 (1958).

A. K. Podolsak, Ph. D. Thesis, Monash University, (1994). E. J. Schaller, P. R. Sperry, and J. C. Thiebeault, “Water Soluble Polymers: Beauty with Performance”, Ed. by Glass, J. E., Advanced Chemistry Series ofthe American Chemical Society, Vol.213 (1986).

K. C. Tam, Ph. D. Thesis, Monash University (1990).

K. C. Tam, T. Moussa and C. Tiu,Rheo. Acta,28, 112 (1989).

F. Tanaka and S. F. Edwards,J. Non-Newtonian Fluid Mech.,43, 273 (1992).

K. C. Taylor and Nasr-EI-Din, SPE Paper29008, 675 (1995).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Tiu, C., Nicolae, G. & Tam, K.C. Rheological properties of hydrophobically modified alkali-swellable acrysol emulsions. J Polym Res 3, 201–209 (1996). https://doi.org/10.1007/BF01493489

Issue Date:

DOI: https://doi.org/10.1007/BF01493489