Abstract

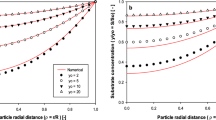

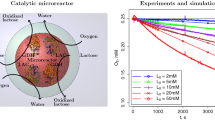

The reversible hydrolysis of maltose to glucose by immobilized glucoamylase entrapped in spherical solid particles is studied theoretically. For this purpose a known kinetic model taking into account these reversible reactions and the competitive synthesis of iso-maltose was adopted. The mass transfer limitations in the bulk liquid and in the pores of the particles containing the enzyme are considered, using Fick's law. On the basis of mathematical modelling the optimum conditions for biocatalyst performance are established. An appropriate combination of particle size and initial substrate concentration may lead to reduction of undesirable mass transfer resistance and therefore product inhibition and to an improved selectivity of the biocatalyst with respect of glucose formation.

Similar content being viewed by others

Abbreviations

- C i kmoles/m3 :

-

current concentration ofi-th component along the radius

- C oi kmoles/m3 :

-

bulk concentration ofi-th component

- C *i kmoles/m3 :

-

concentrations ofi-th component on the pellet surface

- D si ,D i m2/s:

-

internal and molecular diffusion coefficient ofi-th component

- W M kmoles/m3·s:

-

reaction rate of maltose hydrolysis

- W IM kmoles/m3·s:

-

reaction rate of iso-maltose formation

- W G kmoles/m3·s:

-

reaction rate of glucose production

- R 0 m:

-

pellet radius

- r m:

-

current radius of the pellet

- t s:

-

time coordinate

- r 0 :

-

ratio of the time step to the square of the radial coordinate

- Re :

-

Reynolds number =w·R/v

- Sc :

-

Schmidt number =v/D

- Bi :

-

Biot number = βR/D

- A j ,B, C j :

-

coefficients in the system of linear equations, Eq. (8)

- X i :

-

dimensionless degree of transformation

- NR :

-

number of independent reactions

- N :

-

number of division sections of the pellet radius

- G kmoles/m3 :

-

concentration of glucose

- M kmoles/m3 :

-

concentration of maltose

- IM kmoles/m3 :

-

concentration of isomaltose

- K m kmoles/m3 :

-

Michaelis constant

- V max kmoles/m3·s:

-

maximum reaction rate in Eq. (6)

- K i kmoles/m3 :

-

inhibition constant

- K 1eq ,K 2eq :

-

equilibrium constants in Eq. (6)

- τ, h:

-

steps along the time and radial coordinate in the pellet

- β m/s:

-

mass transfer coefficient

- ϱ :

-

dimensionless radius of the pellet

- ɛ :

-

computation accuracy

- i :

-

number of reaction component

- j :

-

index along the radius of the pellet

- k :

-

index along the time coordinate

References

Lloyd, N.; Nelson, W.: Glucose and fructose-containing sweeteners from starch. In Wistler, R.; Bemiller, J.; Paschall, E. (Eds.): Starch: Chemistry and Technology. (Second edition) p. 612, Academic Press 1984

Rollings, J.E.; Thompson, R.: Kinetics of enzymatic starch liquefaction. Ann. N. Y. Acad. Sci: Enzyme Engineering 7 v. 434 p. 140–143

Stewart, G.G.: The biotechnological relevance of starch-degrading enzymes. CRC Critical Reviews in Biotechnology, 5 (1982) 89–93

Kearsley, M.W.;Satii, S.H.;Tregakis, I.: The production and properties of glucose syrups. Starch 32 (1980) 169–174

Roberts, G.W.;Satterfield, C.N.: Effectiveness factor for porous catalysts. I&EC Fundamentals 4 (1965) 288–293

Yankov, D.: Characterization of glucoamylase entrapped in polyacrylamide gel. Diffusion coefficients and kinetic constants. Proceedings of 11th CHISA Congress, Praha, Czech Republic, 29.08–03.09.1993, Poster No A-122

Muhr, A.;Blanshard, M.: Diffusion in gels. Polymer, 23 (1982) 1012–1026

Aerov, M.; Todes, O.: Hydrodynamic and heat bases of operation of stationary and fluidized bed reactors, p. 479, Leningrad, Chemistry, 1968 (in Russian)

Beschkov, V.;Marc, A.;Engasser, J.M.: A kinetic model for hydrolysis and synthesis of maltose, isomaltose and maltotriose by glucoamylase. Biotechn. Bioeng. 26 (1984) 22–26

Slin'ko, M.;Beskov, V.: Methods of modelling catalytic processes on analogous and digital computers, p. 9, Novosibirsk, Nauka, 1972 (in Russian)

Godunov, S.K.;Ryabenkii, V.S.: Finite differences schemes. Moskow, Nauka, 1973 (in Russian)

Author information

Authors and Affiliations

Additional information

This work was accomplished with thanks to the financial support of the Bulgarian National Fund for Scientific Investigations —Grant No. MU-1-BE/93.

Rights and permissions

About this article

Cite this article

Yankov, D., Sapundzhiev, C. & Beschkov, V. Modelling of enzyme hydrolysis of maltose in a single pellet of immobilized biocatalyst. Bioprocess Engineering 14, 219–222 (1996). https://doi.org/10.1007/BF01464737

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF01464737