Abstract

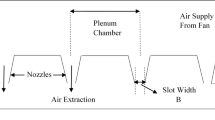

The drying performance and the forces generated by a pair of radial jets impinging on a plane surface are studied experimentally and compared with a pair of in-line (axial) jets. The reattachment rings of the radial jets are visualized by liquid-crystal-thermography. The results of the drying experiments are presented in terms of Sherwoodnumbers. The results of the surface force measurements are presented in terms of force coefficients. The effects of flow exit angle, exit velocity, horizontal nozzle spacing and vertical nozzle to surface distance on mass transfer and net surface force are discussed. Results show that drying performance of a pair of radial jets with an exit angle towards the surface of 10° is 18% higher than that of a pair of in-line jets. The surface force of impinging radial jets depends on the exit angle. A global pressure force on the surface is typical for jets directed towards the surface, while a global lifting force is found when the jet is initially directed away from the surface. Radial jets have a high potential in drying applications for force sensitive products and when high drying rates and/or small suction forces are of interest.

Zusammenfassung

Die Trocknungs-und Kraftwirkung von Prallstrahlen auf eine ebene Fläche aus einem Paar von Radialdüsen wird experimentell untersucht und mit einem Axialdüsenpaar verglichen. Die Wiederanglegering der Radialdüsenströmung werden mittels der Flüssigkristallthermographie sichtbar gemacht. Die Ergebnisse der Trocknungsversuche werden mittels Sherwoodzahlen dargestellt. Die Ergebnisse der Strahlkraftmessungen werden durch Kraftbeiwerte dargestellt. Die Einflüsse des Strömungsaustrittswinkels, der Strömungsaustrittsgeschwindigkeit, des horizontalen Düsenabstandes und des vertikalen Abstandes zwischen Düsenmündung und Oberfläche auf den Stoffübergang und auf die Oberflächenkraft werden betrachtet. Die Ergebnisse zeigen, daß die Trocknungsleistung eines Radialdüsenpaares mit einem zur Oberfläche gerichteten Abströmwinkel von 10° um 18% über der des entsprechenden Axialdüsenpaares liegt. Die Oberflächenkraft von radialen Prallstrahlen wird durch den Strömungsaustrittwinkel beeinflußt. Globale Druckkräfte sind typisch für Strahlen, die in Richtung der Oberfläche austreten, während globale Saugkräfte bei Strahlen auftreten, die zunächst von der Oberfläche weggelenkt werden. Radialdüsen haben ein hohes Anwendungspotential bei mechanisch nur gering beanspruchbaren Gütern, wenn hohe Trocknungsraten und/oder geringe Saugkräfte von Interesse sind.

Similar content being viewed by others

Abbreviations

- A m2 :

-

area

- A E m2 :

-

nozzle exit cross section

- b m:

-

nozzle exit width

- c F :

-

force coefficient [=F/(ρ L υ 2 E A E )]

- c P :

-

pressure coefficient [=(p−p ∞)/(0.5 ρ L υ 2 E )]

- c P J/(kgK):

-

specific heat at constant pressure

- c W J/(kgK):

-

specific heat of liquid water

- D m2/s:

-

mass diffusivity

- d h m:

-

hydraulic diameter of exit cross section

- F N:

-

net surface force

- f :

-

relative nozzle area [=πr 2 i /s 2]

- g m/s2 :

-

gravitational acceleration

- h m:

-

vertical spacing between RJ nozzle exit and impingement surface

- Δh v kJ/kg:

-

enthalpy of vaporization

- L m:

-

characteristic length

- M kg:

-

mass

- M mol kg/kmol:

-

molecular weight

- M kg/s:

-

mass flow rate

- P W N/m2 :

-

partial pressure of steam

- P ∞ N/m2 :

-

atmospheric or ambient pressure

- r i m:

-

inner nozzle radius

- r 0 m:

-

outer nozzle radius

- r R m:

-

radius of reattachment ring

- s m:

-

centerline spacing between both nozzles

- s′ m:

-

clear spacing between RJ nozzle exits

- s 1,s 2 m:

-

dimensions of plane surface

- s nW m:

-

wall thickness of nozzle (=r 0−r i )

- T K:

-

temperature

- t s:

-

drying time

- \(\dot V\) m3/s:

-

volumetric flow rate

- υ E m/s:

-

average nozzle exit velocity

- X ev kg/kg:

-

relative evaporated mass of water

- x kg/kg:

-

vapor content of the air

- β m/s:

-

average mass transfer coefficient

- η Ns/m2 :

-

absolute viscosity

- θ °:

-

angle of flow exit (RJ nozzle) relative to plane surface

- θ R °:

-

angle of reattachment

- v m2/s:

-

kinematic viscosity

- ρ kg/m3 :

-

density

- ρ w kg/m3 :

-

partial density of steam

- τ K:

-

saturation temperature

- φ:

-

relative humidity

- W :

-

water

- F :

-

air flow

- S :

-

surface

- ∞:

-

atmospheric

- ″:

-

saturation

References

Martin, H.: Heat and Mass Transfer between Impinging Jets and Solid Surfaces. Advances in Heat Transfer 13 (1977) 1–60

Page, R. H.;Hadden, L. L.;Ostowari, C.: Theory for Radial Jet Reattachment Flow. AIAA Journal 27 (11) (1989) 1500–1505

Page, R. H.; Ostowari, C.; Carbone, J. S.: Radial Jet Flow. Proceedings of the 4th International Symposium on Flow Visualization, Paris, France (1986) 513–521

Page, R. H.;Carbone, J.;Ostowari, C.: Radial Jet Reattachment Force. Experiments in Fluids 8 (5) (1990) 13–17

Page, R. H.; Ostowari, C.; Seyed-Yagoobi, J.: Infrared Images of Jet Impingement. Proceedings of 20th Int. Congress on High Speed Photography and Photonics, SPIE 1801 (1992)

Page, R. H.;Kiel, R.: Utilization of Radial Jet Reattachment (RJR) for Industrial Drying. Proceedings of Forum on Industrial and Petro-Chemical Applications of Fluid Mechanics, ASME FED-Vol 100 (1990) 71–77

Gruber, T. C.: The Interaction between Two Radial Jets. Master of Science Thesis, Mechanical Engineering Department, Texas A&M University (1993)

Laschefski, H.;Holl, A.;Grosse-Gorgemann, A.;Mitra, N. K.;Page, R. H.: Flow Structure and Heat Transfer of Radial and Axial Jet Reattachment on a Flat Plate. ASME WAM, HTD-Vol. 210 (1992) 123–131

Laschefski, H.: Numerische Untersuchung der dreidimensionalen Strömungsstruktur und des Wärmeübergangs bei ungeführten und geführten, laminaren Freistrahlen mit Prallplatte. VDI Fortschrittsberichte, Reihe 19, No. 72 (1994)

Andrews, M.: Modeling of Turbulent Radial Jet Reattachment. International Symposium on Heat and Mass Transfer in Energy Systems and Environmental Effects, Cancun, Mexico (1993)

Koswig, H. D. et al.: Selected Topics in Liquid Crystal Research, Berlin: Akademie-Verlag 1990

Page, R. H.: Axisymmetric Gas Jets: Surface Impingement Phenomena. Proceedings of 14th Canadian Congress of Applied Mechanics CANCAM 1 (1993) 10–19

Schlünder, E. U.: Warme- und Stoffübertragung zwischen Gut und Aufprallendem Düsenstrahl. Chem.-Ing.-Techn., 39. Jahrgang, Heft 9/10 (1967) 578–584

Baehr, H. D.: Thermodynamik. Springer Verlag 1984

Churchill, S. W.: A Correlating Equation for almost Everything. Thornton, Etaner Press 1982

Krischer, O.: Die Wissenschaftlichen Grundlagen der Trocknungstechnik. Springer Verlag 1978

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Peper, F., Leiner, W. & Fiebig, M. Drying performance and surface forces of a pair of impinging radial jets. Heat and Mass Transfer 30, 313–320 (1995). https://doi.org/10.1007/BF01463922

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF01463922