Abstract

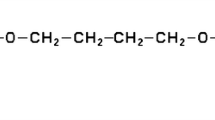

A solid state extrusion technique is applied as to produce oriented block copoly(ether ester) under various physical conditions. The morphology of the extruded samples is characterized in relation to the extrusion parameters and hard segment compositions of the polymer, using thermal analysis and X-ray methods. The lateral dimensions of the crystalline domains are found to be approximately 150 Å depending on the extrusion conditions. The statistics of the long range periodicity of the structure along the extrusion direction is in agreement with a one-dimensional two phase model, the crystalline portion of which does not vary much in thickness (35 – 45 Å). The unexpected increase in the long period and the thermal shrinkage suggest the existence of strained interlamellar amorphous chains (tie molecules). The observed variations in tensile properties are interpreted under the assumption that both the number of such tie molecules and their fully extended lengths are determined by the hard segment composition and the extrusion conditions. It is also argued that the increase in the glass transition temperature is not only a function of the composition of hard segments in the amorphous phase but also of the number of strained tie molecules.

Similar content being viewed by others

References

Cella RJ (1977) Encyclopedia of Polymer Science and Technology, J. Wiley & Sons, New York Supp Vol II, p 485

Buck WH, Cella RJ, Gladding EK, Wolfe Jr JR (1974) J Polymer Sci, Polym Symp 48:47

Shen M, Mehra U, Niinomi M, Koberstein JT, Cooper SL (1974) J Appl Phys 45:4182

Wegner G, Fujii T, Meyer W, Lieser G (1978) Angew Makromol Chem 74:295

Lilaonitkul A, West JC, Cooper SL (1976) J Macromol Sci, Phys Ed 12:563

Bandara U, Dröscher M (1983) Colloid Polym Sci 261:26

Zhu L-L, Wegner G (1981) Makromol Chem 182:3625

Wegner G, Zhu L-L, Lieser G, Tu H-L (1981) Makromol Chem 182:231

Dröscher M, Regel W (1979) Polym Bull 1:551

Dröscher M (1982) Adv Polym Sci 47:119

Bandara U, Dröscher M (1982) Rheol Acta 21:435

Bandara U, Dröscher M (1982) Angew Makromol Chem 107:1

Zachariades AE, Mead WT, Porter RS (1981) Chem Rev 80:351

Hoeschele GK (1977) Angew Makromol Chem 58/59:299

Kratky O, Pilz I, Schitz PI (1966) J Colloid Interface Sci 21:24

Wilke W (1981) Colloid Polym Sci 259:577

Blundell DJ (1970) Acta Cryst A 26:472

Welte W, Kreutz W (1979) Adv Polym Sci 30:161

Bonart R (1966) Koll — Z u Z Polymere 211:14

Hosemann R (1950) Koll ZS 119:129

Hermans JJ (1974) Rec Trav Chim Phys-Bas 63:211

Bonart R (1975) Proceedings of the International Wool Textile Research Conference, Vol II, Aachen

Porod G (1951) Koll ZS 124:83

Krause S (1972) J Macromol Sci Rev Macromol Chem C 7:251

Wunderlich B (1980) “Macromolecular Physics”, Academic Press, New York, Vol 3, p 191

Illers KH (1980) Colloid Polym Sci 258:117

Desborough IJ, Hall IH (1977) Polymer 18:825

Fischer EW, Goddar H, Schmidt GF (1968) Makromol Chem 119:170

Riva F, Forte A, Della Monica C (1981) Colloid Polym Sci 259:606

Matsu M, Geshi K, Moriyama A, Sanatari C (1982) Macromolecules 15:193

Noether HD (1978) Polym Preprints, Amer Chem Soc/Div Polym Chem 19:320

Takayanagi M, Imada K, Kajiyama T (1966) J Polym Sci C 15:263

Bonart R (1979) Polymer 20:1389

van Krevelen DW (1972) Properties of Polymers — Correlations with Chemical Structure, Elsevier Publishing Company, Amsterdam p 161

Wegner G, Bandara U in preparation

Samuels SL (1974) Structured Polymer Properties, J Willey & Sons, New York, p 215

Bonart R (1977) Angew Makromol Chem 58/59:259

Peterlin A (1977) (eds) Cifferri A, Ward IM, Ultra-High Modulus Polymers, Applied Science Publishers, London, p 36

Gordon M, Taylor JS (1952) J Appl Chem 2:493

Author information

Authors and Affiliations

Additional information

Herrn Dr. Dr. h. c. H. Hellmann zum 70. Geburtstag gewidmet.

Part 3 cf. lit [11]

Rights and permissions

About this article

Cite this article

Bandara, U., Dröscher, M. & Thomas, E.L. Solid state extrusion of thermoplastic elastomers 4. Colloid & Polymer Sci 262, 538–550 (1984). https://doi.org/10.1007/BF01451517

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF01451517