Abstract

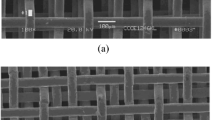

To obtain coatings of thickness to 0.7 mm or more with controllable porosity, having in contrast with the traditional coatings a more uniform chemical composition and properties that are uniform through the thickness, we propose to create on the surface of the part that is being coated a periodic relief of a definite geometry, consisting of alternating protuberances (ribs) and depressions, after which diffusional saturation is performed. The inter-rib “channels” provide for accelerated diffusion of the saturating element through the entire thickness of the coating, equal to the rib height. Thus, the structure of the diffusion coating will be determined not only by the technological factors of diffusional saturation (temperature, duration, chemical composition of the medium and of the material being coated) but also by the geometry of the relief, which makes it possible to broaden the capabilities for varying the structural state of the diffusion coatings. The multifactor nature of the proposed method leads to certain difficulties in developing the regimes for obtaining coatings with the desired periodic structure. In this connection it is advisable to formulate a mathematical model that will make it possible to predict the structure of the obtained coatings. The mathematical model consists of a system of differential equations that can be solved numerically and describe the changes in time of the concentration of the coating elements and the location of the interphase boundaries. The adequacy of the proposed mathematical model is confirmed herein.

Similar content being viewed by others

References

B. N. Arzamasov, V. N. Simonov, M. A. Khasyanov, et al., “Mechanochemicothermal surface treatment of machine parts,” Vesm. Mashinostr., No. 7, 32–35 (1993).

N. N. Zubkov, “Surface working of materials by deformation cutting,” in: New Technology, Equipment, Fixtures, Tools for Mechanical Working and Assembly: Proceedings of MDNTP [Moscow House of Scientific and Technical Propaganda] Seminar [in Russian], pp. 30–33, MDNTP, Moscow (1989).

B. N. Arzamasov, Chemico-Thermal Treatment of Metals in Activated Gaseous Media [in Russian], Mashinostroenie, Moscow (1979).

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 6, pp. 6–9, June, 1994.

Rights and permissions

About this article

Cite this article

Simonov, V.N., Khasyanov, M.A. Mathematical modeling of the formation of diffusion coatings with periodic structure. Met Sci Heat Treat 36, 287–291 (1994). https://doi.org/10.1007/BF01401069

Issue Date:

DOI: https://doi.org/10.1007/BF01401069