Conclusions

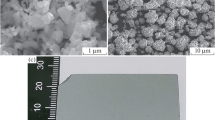

We studied the influence of a number of technological parameters (heat-process temperature, dispersion of solid phase, pH, and concentration of suspension) on the rheological properties of the water suspensions and certain technical properties of castings and materials made from yttria-stabilized ZrO2, obtained by the method of coprecipitation from salt solutions.

We demonstrated the essential influence of the structure of the original powders, the content of Y2O3, and the bonded chlorides on the properties of the castings and the sintered material.

Similar content being viewed by others

Literature cited

Science and Technology of Zirconia: Proc. 1st Int. Conf., Eds. A. H. Hener and L. W. Hobbs, Columbus, Ohio (1981).

R. I. Brook, Proc. Brit. Ceram. Soc., No. 32, 7–24 (1982).

S. Yu. Pliner, Yu. S. Toropov, D. S. Rutman, et al., Ogneupory, No. 11, 4–6 (1984).

D. S. Rutman, Yu. S. Toropov, Yu. M. Polezhaev, et al., in: Scientific Principles of Material Behavior [in Russian], Nauka, Moscow (1981), pp. 27–38.

V. B. Glushkova and É. K. Keler, in: High Temperture Materials for MHD Equipment [in Russian], Nauka, Moscow (1977), pp. 46–51.

D. S. Rutman, Yu. S. Toropov, Yu. M. Galkin, et al., Refractory Concretes for Soaking Pits [Materials from the All-Union Conference], Technology and Use of Refractories [in Russian], Tr. East Inst. Refractories/VostIO, No. 13, 87–105 (1972).

I. M. Vasserman, Chemical Precipitation from Solutions [in Russian], Nauka, Leningrad (1977).

G. P. Kalliga, Casting Zirconia Refractories [in Russian], Metallurgiya, Moscow (1964).

A. G. Kraulov and G. V. Kukolev, Theoretical and Technological Investigations in the Sphere of Refractories [in Russian], Collection of Papers, Ukrainian Institute of Refractories, Kharkov University (1965), pp. 167–179.

F. F. Lange, B. I. Davis, and I. A. Aksay, J. Am. Ceram. Soc.,66, No. 6, 407–408 (1983).

G. S. Khodakov, Physics of Milling [in Russian], Nauka, Moscow (1972).

Yu. E. Pivinskii, Ogneupory, No. 6, 49–60 (1982).

K. Dei and D. Selbin, Theoretical Inorganic Chemistry [in Russian], Mir, Moscow (1976).

A. G. Dobrovol'skii, Slip Casting [in Russian], Metallurgiya, Moscow (1977).

A. A. Furman, Inorganic Chlorides (Chemistry and Technology) [in Russian], Khimiya, Moscow (1980).

Yu. E. Pivinskii and T. F. Baranova, Ogneupory, No. 6, 22–27 (1984).

Yu. E. Pivinskii and V. A. Bevz, Izv. Akad. Nauk SSSR, Neorg. Mater.,17, No. 9, 1706–1709 (1981).

Additional information

Translated from Ogneupory, No. 1, pp. 24–28, January, 1986.

Rights and permissions

About this article

Cite this article

Pivinskii, Y.E., Dabizha, A.A., Ul'rikh, V.I. et al. Investigating slip casting of ceramics based on stabilized ZnO2 obtained by the chemical coprecipitation method. Refractories 27, 27–33 (1986). https://doi.org/10.1007/BF01398284

Issue Date:

DOI: https://doi.org/10.1007/BF01398284