Conclusions

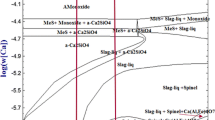

Among the experimental additives introduced into the composition of the magnesia-spinellid bodies, the highest resistance to the synthetic slag is exhibited by the fused and the sintered spinels and electrocorundum, and the least resistance is shown by the tricalcium and dicalcium silicates. Forsterite is the most stable silica-bearing phase.

The plasticizer additions (refractory clays or bentonite) that ensure satisfactory shaping properties of the bodies are found to have an adverse effect on the slag-resistance of the systems: the interaction period required for the initiation of erosive wear decreases with increasing plasticizer content. The bentonite content in the body must not exceed 3% and the refractory clay content must not exceed 5–6%.

A direct correlation with a correlation coefficient of 0.94–0.99 was established between the amount of the direct bonds existing in the refractory and the interaction period up to the initiation of erosive wear; this fact indicates the significant effect of the refractory structure and the phase distribution on the erosive wear. When the refractory clay amounts to 7–10%, erosive wear is observed within the very initial stage of interaction.

Under the action of the molten synthetic slag, one does not observe much difference in the destruction of the systems containing the Latnensk and the Novoraisk clays; on the other hand, the systems containing the Latnensk clay possess a high resistance to the molten mixture of the synthetic and the converter slags. The mixture of the synthetic and the converter slags has a significant destructive action.

We showed that it is advisable to introduce fused spinel and electrocorundum additives into the composition of the magnesia-spinellid based ramming bodies.

Similar content being viewed by others

Literature cited

T. V. Noskova and N. N. Perevalov, Obzor. Inform., Chermetinformatsiya, Ser. Staleplavil'noe Proizvodstvo (Steel Making Industry), No. 1, 1–36 (1981).

S. V. Kolpakov and O. L. Bondarenko, Stal', No. 6, 513–516 (1976).

B. A. Velikin, A. K. Karklit, S. V. Kolpakov, et al., Refractory Lining of Steel Casting Ladles [in Russian], Metallurgiya, Moscow (1980).

D. I. Gavrish, Yu. D. Kuznetsov, L. M. Davydov, et al., Ogneupory, No. 2, 1–8 (1981).

Yu. D. Kuznetsov, S. A. Suvorov, A. D. Mel'nikov, and A. M. Smilovitskii, Izv. Akad. Nauk SSSR, Neorg. Mater.,19, No. 8, 1361–1364 (1983).

K. Furumi and H. Ando, Taikabutsu (Refractories),26, No. 199, 379–386 (1974).

A. D. Mel'nikov, S. A. Suvorov, Yu. D. Kuznetsov, and V. V. Yakovenko, Zavod. Lab., No. 11, 1365–1367 (1978).

Yu. D. Kuznetsov, in: Refractories — Investigations and Production [in Russian], Metallurgiya (MChM SSSR), Moscow (1983), pp. 15–19.

P. E. Dan'ko and A. G. Popov, Advanced Mathematics in Exercises and Problems [in Russian], Part II, Vysshaya Shkola, Moscow (1974).

Author information

Authors and Affiliations

Additional information

Translated from Ogneupory, No. 1, pp. 5–9, January, 1986.

Rights and permissions

About this article

Cite this article

Kuznetsov, Y.D., Yakovenko, L.F. A study of the slag-induced wear of the refarctories made from magnesia-spinellid bodies with an argillaceous binder. Refractories 27, 3–8 (1986). https://doi.org/10.1007/BF01398278

Issue Date:

DOI: https://doi.org/10.1007/BF01398278