Conclusions

A scale-resistant shrink-free ramming compound was developed on the basis of chromite ore, electrocorundum, fireclay, and phosphate bond.

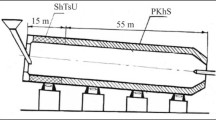

Industrial trials were carried out with the compounds in steel factories in furnaces with walking hearths in mills 260 and 350/500. The resistance of the rammed linings in the soaking zone of the furnace was twice that of the resistance of chrome-magnesite brick structure.

Studies of the samples after service established that the compound had been densified in the working zone, possibly as a result of the formation of a mullite growth between the spinel grains.

Similar content being viewed by others

Literature cited

Ya. A. Orlovskii, Chern. Metall., Bull. NTI, No. 5 (1976).

H. Stein, Kelpzig Fachberichte,81, No. 7 (1973).

Author information

Authors and Affiliations

Additional information

Translated from Ogneupory, No. 2, pp. 9–13, February, 1980.

Rights and permissions

About this article

Cite this article

Startsev, D.A., Tetyaeva, L.P., Zamyatin, S.R. et al. Lining walking-hearth soaking pits furnaces with plastic refractories. Refractories 21, 77–80 (1980). https://doi.org/10.1007/BF01398137

Issue Date:

DOI: https://doi.org/10.1007/BF01398137