Conclusions

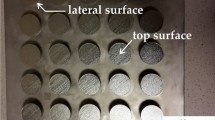

The authors have developed the principles of guniting the monolithic lining of steel-teeming ladles with semidry masses. Determination of the wetting of a vitrified siliceous monolithic lining with aqueous solutions of additives and suspensions of these solutions, plasticizing additives, and refractory filler has shown that a coating can be deposited onto the surface of a monolithic lining. Formation of a ceramic bond between the coating and the vitrified surface of a monolithic lining takes place at high temperatures (900°C or above). Masses of siliceous, aluminosilicate, and periclase-chromite compositions have been developed for guniting the monolithic lining of steel-teeming ladles.

A procedure for guniting the monolithic lining of 180- and 350-ton steel-teeming ladles has been developed and tested. The best results have been obtained with use of gunite masses of periclase-chromite composition.

Similar content being viewed by others

Literature cited

Yu. D. Kuznetsov, V. V. Yakovenko, and A. D. Mel'nikov, Obzor. Inf., Chermetinformatsiya, Ser. 11, No. 1 (1978).

A. K. Karklit, Yu. D. Kuznetsov, B. A. Velikin, et al., Ogneupory, No. 6, 4–8 (1975).

Yu. D. Kuznetsov, B. A. Velikin, B. A. Simanovskii, et al., Ogneupory, No. 10, 38–42 (1976).

Yu. A. Pirogov, M. I. Prokopenko, A. A. Ivankovskii, et al., Ogneupory, No. 1, 6–10 (1979).

V. G. Flyagin, D. S. Rutman, A. D. Popov, et al., Ogneupory, No. 9, 29–32 (1977).

H. Keden, E. Namba, H. Haisi, et al., Taikabutsu,30, No. 4 (243), 218–223 (1978).

H. Tanako, M. Eiraku, and H. Furumi, ibid., 223–226.

W. D. Kingery, Measurements at High Temperatures [Russian translation], Moscow (1963).

S. A. Suvorov, A. D. Mel'nikov, and Yu. D. Kuznetsov, Ogneupory, No. 4, 59–61 (1980).

B. A. Velikin, A. K. Karklit, S. V. Kolpakov, et al., Lining of Steel-Teeming Ladles [in Russian], Moscow (1980).

S. A. Suvorov, A. D. Mel'nikov, Yu. D. Kuznetsov, et al., Ogneupory, No. 6, 30–32 (1980).

V. A. Lazovskii, L. F. Yakovenko, E. I. Davydenkov, et al., Ogneupory, No. 10, 46–51 (1976).

Yu. D. Kuznetsov, B. A. Velikin, L. M. Davydov, et al., Ogneupory, No. 8, 26–30 (1975).

F. F. Ocheretnyuk, V. A. Kopeikin, V. S. Kliment'eva, et al., Ogneupory, No. 3, 25–27 (1978).

B. A. Velikin, E. I. Davydenkov, L. M. Demidenko, et al., Inventor's Certificate 499, 972, Otkryt., Izobret., Prom. Obraztsy, Tov. Zn., No. 3, 29 (1976).

Yu. D. Kuznetsov, V. A. Erastov, E. I. Davydenkov, et al., Inventor's Certificate 591, 436, Otkryt., Izobret., Prom. Obraztsy, Tov. Zn., No. 5, 70 (1978).

A. D. Mel'nikov, S. A. Suvorov, Yu. D. Kuznetsov, et al., Zavod. Lab., No. 11, 1365–1367 (1978).

Author information

Authors and Affiliations

Additional information

Translated from Ogneupory, No. 6, pp. 25–30, June, 1981.

Rights and permissions

About this article

Cite this article

Kuznetsov, Y.D., Davydov, L.M., Yakovenko, L.F. et al. Guniting of the monolithic lining of steel-teeming ladles. Refractories 22, 328–333 (1981). https://doi.org/10.1007/BF01397999

Issue Date:

DOI: https://doi.org/10.1007/BF01397999