Abstract

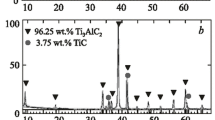

Research has been done on the reduction of a combined charge containing titanium dioxide, boron carbide, and carbon black at 1333-2000°C for various times. Semifinished products reduced for not more than 30 min do not sinter and do not require grinding, but can be sintered with the formation of a material in the TiB2-TiC system. The grinding rate for incompletely reduced products increases as the reduction temperature is reduced. Mixtures containing 64 mass% TiB2 and 36 mass % TiC formed by reducing the combined charge are ground more rapidly and with less contamination by iron than a control mixture of 80 mass% TiB2 and 20 mass% TiC formed from the powders. It is concluded that it is best to prepare the final TiB2-TiC mixture by reducing a combined charge, which reduces the costs in preparing the mixtures before sintering.

Similar content being viewed by others

References

V. M. Gropyanov and L. M. Bel'tyukova, “Sintering and recrystallization of ZrC-ZrB2 pressings,” Porosh. Metallurgiya, No. 7, 40–47 (1968).

R. E. Murasko, V. N. Sumarokov, L. I. Struzh, and S. A. Shvab, “Use of refractory carbides for making components of evaporator systems,” in: Carbides and Alloys Based on Them [in Russian], Naukova Dumka, Kiev (1976), pp. 235–240.

S. A. Shvab, “Research on making evaporator elements from titanium diboride containing 20% titanium carbide,” in: Materials and Components Made by Powder Metallurgy Methods [in Russian], Inst. Probl. Materialovedeniya AN Ukr. SSR, Kiev (1975), pp. 72–77.

P. S. Kislyi, S. A. Shvab, L. A. Gaevskaya, et al., “Structure and properties of a titanium diboride material containing 20% titanium carbide,” Porosh. Metallurgiya, No. 9, 35–38 (1973).

G. V. Samsonov, “Interactions of titanium, zirconium, and tungsten borides with their carbides," in: Aspects of Powder Metallurgy and Material Strength [in Russian], Izd. AN Ukr. SSR, Kiev (1959), Issue 7, pp. 72–98.

I. V. Uvarova and V. V. Panichkina, “A simplified method of measuring specific surface from the physical desorption of nitrogen,” Zav. Lab., No. 3, 306–311 (1960).

V. V. Skorokhod, Rheological Principles of Sintering Theory [in Russian], Naukova Dumka, Kiev (1972), 151 pp.

S. S. Saltykov, Stereometric Metallography [in Russian], Metallurgizdat, Moscow (1958), 446 pp.

Additional information

Materials Science Institute, Ukrainian National Academy of Sciences, Kiev. Translated from Poroshkovaya Metallurgiya, Nos. 3/4(384), pp. 114–118, March–April, 1996. Original article submitted March 9, 1994.