Conclusions

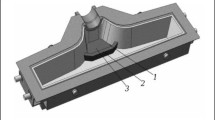

During the time of mastering the operation of the oxygen converter shop at Dnepr Metallurgical Combine the service of refractories in the slide gates of steel teeming ladles was investigated. It was shown that to obtain a large number of billets of a broad range of steels it is necessary to use composite magnesite plates with periclase inserts. In this case mullite-corundum plates do not provide breakdown-free teeming.

It was established that magnesite nozzles and lower nozzles may be replaced successfully with forsterite ones.

Petrographic investigations of a periclase insert were conducted. A probable mechanism of wear of the refractories during teeming was proposed and measures were proposed for improving the service of the refractories.

Similar content being viewed by others

Author information

Authors and Affiliations

Additional information

Translated from Ogneupory, No. 12, pp. 40–43, December, 1986.

Rights and permissions

About this article

Cite this article

Sergienko, V.S., Evtushenko, V.B., Publika, A.Y. et al. The service of reactories in the slide gates of 250-ton steel teeming ladles. Refractories 27, 705–708 (1986). https://doi.org/10.1007/BF01387234

Issue Date:

DOI: https://doi.org/10.1007/BF01387234