Abstract

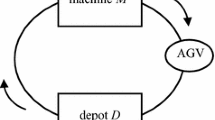

This paper presents a mathematical programming model to help select equipment for a flexible manufacturing system, i.e., the selection of the types and numbers of CNC machines, washing stations, load/unload stations, transportation vehicles, and pallets. The objective is to minimize equipment costs and work-in-process inventory cost, while fulfilling production requirements for an average period. Queueing aspects and part flow interactions are considered with the help of a Jacksonian-type closed queueing network model in order to evaluate the system's performance. Since the related decision problem of our model can be shown to be NP-complete, the proposed solution procedure is based on implicit enumeration. Four bounds are provided, two lower and two upper bounds. A tight lower bound is obtained by linearizing the model through the application of asymptotic bound analysis. Furthermore, asymptotic bound analysis allows the calculation of a lower bound for the number of pallets in the system. The first upper bound is given by the best feasible solution and the second is based on the anti-starshaped form of the throughput function.

Similar content being viewed by others

References

Boxma, O.J., Rinnooy Kan, A.H.G., and van Vliet, M., “Machine Allocation Problems in Manufacturing Networks,”European Journal of Operational Research, Vol. 45, pp. 47–54 (March 1990).

Co, H.C. and Wysk, R.A., “The Robustness of CAN-Q in Modeling Automated Manufacturing Systems,”International Journal of Production Research, Vol. 24, No. 6, pp. 1485–1503 (November–December 1986).

Dallery, Y. and Frein, Y., “An Efficient Method to Determine the Optimal Configuration of a Flexible Manufacturing System,”Proceedings of the 2nd ORSA/TIMS Conference on Flexible Manufacturing Systems: Operations Research Models and Applications, K.E. Stecke and R. Suri (Eds.), Elsevier Science Publishers B.V., Amsterdam, pp. 269–282 (1986).

Dallery, Y. and Suri, R., “Approximate Disaggregation and Performance Bounds for Queueing Networks with Multiple-Server Stations,”Performance Evaluation Review, Vol. 14, No. 1, pp. 111–128 (May 1986).

Garey, M.R. and Johnson, D.S.,Computers and Intractability, W.H. Freeman and Company, San Francisco, CA (1979).

Gordon, W.J. and Newell, G.F., “Closed Queueing Systems with Exponential Servers,”Operations Research, Vol. 15, No. 2, pp. 254–265 (1967).

Jackman, J. and Johnson, E., “The Role of Queueing Network Models in Performance Evaluation of Manufacturing Systems,”Journal of the Operational Research Society, Vol. 44, No. 8, pp. 797–807 (1993).

Lee, H.F., Srinivasan, M.M., and Yano, C.A., “Algorithms for the Minimum Cost Configuration Problem in Flexible Manufacturing Systems,”International Journal of Flexible Manufacturing Systems, Vol. 3, Nos. 3/4, pp. 213–230 (1991).

Luenberger, D.G.,Linear and Nonlinear Programming, Addison Wesley, Reading, MA (1984).

Shanthikumar, J.G. and Yao, D.D., “Optimal Server Allocation in a System of Multi-Server Stations,”Management Science, Vol. 33, No. 9, pp. 1173–1180 (September 1987).

Shanthikumar, J.G. and Yao, D.D., “On Server Allocation in Multiple Center Manufacturing Systems,”Operations Research, Vol. 36, No. 2, pp. 333–342 (March–April 1988).

Shanthikumar, J.G. and Yao, D.D., “Optimal Buffer Allocation in a Multicell System,”International Journal of Flexible Manufacturing Systems, Vol. 1, No. 3, pp. 347–356 (June 1989).

Solot, P., “A Heuristic Method to Determine the Number of Pallets in a Flexible Manufacturing System with Several Pallet Types,”International Journal of Flexible Manufacturing Systems, Vol. 2, No. 3, pp. 191–216 (May 1990).

Solot, P. and van Vliet, M., “Analytical Models for FMS Design Optimization: A Survey,”International Journal of Flexible Manufacturing Systems, Vol. 6, No. 3, pp. 209–233 (July 1994).

Suri, R., “A Concept of Monotonicity and Its Characterization for Closed Queueing Networks,”Operations Research, Vol. 33, No. 3, pp. 606–624 (May–June 1985).

Tetzlaff, U.,Optimal Design of Flexible Manufacturing Systems, Physica Verlag, Heidelberg, Germany (1990).

Tetzlaff, U., “Routing Optimization in Flexible Production Systems,” Working Paper, Department of Decision Sciences and MIS, George Mason University, Fairfax, Virginia (1991).

Tetzlaff, U., “Selection of Manufacturing Equipment for Flexible Production Systems,”Reference Book on Intelligent Design and Manufacturing, A. Kusiak, (Ed.), John Wiley and Sons, New York, NY (1992a).

Tetzlaff, U., “Tool Binding in Flexible Manufacturing Systems,”Proceedings of the DGOR/ORSA Conference on Recent Developments and New Perspectives of Operations Research in the Area of Production Planning and Control, Hagen, Germany (1992b).

Tetzlaff, U., “Capacity Optimization of Flexible Manufacturing Systems Under Budget Constraints,”International Journal of Flexible Manufacturing Systems, Vol. 6, No. 1, pp. 55–67 (January 1994).

van Vliet, M. and Rinnooy Kan, A., “Machine Allocation Algorithms for Job Shop Manufacturing,”Journal of Intelligent Manufacturing, Vol. 2, pp. 83–94 (1991).

Vinod, B. and Solberg, J.J., “The Optimal Design of Flexible Manufacturing Systems,”International Journal of Production Research, Vol. 23, No. 6, pp. 1141–1151 (November–December 1985).

Zahorjan, J., Sevcik, K.C., Eager, D.L., and B. Galler, “Balanced Job Bound Analysis of Queueing Networks,”Communications of the Association for Computing Machinery, Vol. 25, pp. 134–141 (February 1982).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Tetzlaff, U.A.W. A model for the minimum cost configuration problem in flexible manufacturing systems. Int J Flex Manuf Syst 7, 127–146 (1995). https://doi.org/10.1007/BF01358906

Issue Date:

DOI: https://doi.org/10.1007/BF01358906