Abstract

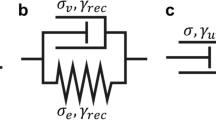

The rheology of concentrated coagulating suspensions is analysed on the basis of the following model: (i) at low shear rates, the shear is not distributed homogeneously but limited to certain shear planes; (ii) the energy dissipation during steady flow is due primarily to the overcoming of viscous drag by the suspended particles during motion caused by encounters of particles in the shear planes. This model is called the “giant floc” model.

With increasing shear rate the distance between successive shear planes diminishes, approaching the suspended particles' diameter at average shear stresses of 88–117 Pa in suspensions of 78 µm particles (glass ballotini coated by a hydrophobic layer) in glycerol — water mixtures, at solid volume fractions between 0.35 and 0.40. Smaller particles form a more persistent coagulation structure. The average force necessary to separate two touching 78 µm particles is too large to be accounted for by London-van der Waels forces; thus coagulation is attributed to bridging connections between polymer chains protruding from the hydrophobic coatings.

The frictional ratio of the glass particles in these suspensions is of the order of 10. Coagulation leads to build-up of larger structural units at lower shear rates; on doubling the shear rate the average distance between the shear planes decreases by a factor of 0.81 to 0.88.

Similar content being viewed by others

Abbreviations

- A :

-

inter-shear plane distance

- A′ :

-

Hamaker constant

- b :

-

radius of primary particles

- f :

-

frictional ratio

- F A :

-

attractive force between two particles

- g :

-

acceleration due to gravity

- H :

-

distance between the surfaces of two particles

- K :

-

proportionality constant in power law

- l :

-

fraction of distance by which a moving particle entrains its neighbours

- l′ :

-

effective length of inner cylinder in the rheometer

- M :

-

torque experienced by inner cylinder during measurements

- n :

-

exponent in power law

- n 0 ,n 1 ,n 2 :

-

constants in extended power law

- NC hex :

-

number of contacts, per mm2, between particles in adjacent layers with an average degree of occupation, assuming a hexagonal arrangement of the particles within the layers

- NC cub :

-

asNC hex, but with a cubical arrangement

- p (τ) dτ :

-

increase of slippage probability when the shear stress increases fromτ toτ + dτ

- q :

-

average coordination number of a particle in a coagulate

- R i :

-

radius of inner cylinder of rheometer

- R u :

-

radius of outer cylinder of rheometer

- t i :

-

time during which particlei moves

- t 0 :

-

time during which a particle bordering a shear plane moves from its rectilinear course, on meeting another particle

- u :

-

angle between the direction of motion, and the line connecting the centers of two successive particles bordering a shear plane

- V A :

-

attractive energy between two particles

- x, y, z :

-

Cartesian coordinates:x — the direction of motion;y — the direction of the velocity gradient

- y 0 ,z 0 :

-

y, z value of a particle meeting another particle, when both are far removed from each other

- Δy 0 :

-

spread iny 0 values

- α :

-

—2/n

- α 0 :

-

capture efficiency

- \(\dot \gamma \) :

-

shear rate

- \(\bar \dot \gamma _N \) :

-

average shear rate calculated for a Newtonian liquid

- δ i :

-

distance by which particlei moves

- δ 0 :

-

distance by which a particle bordering a shear plane moves from its rectilinear course, when it encounters another particle

- Δ :

-

square root of area occupied by a particle bordering a shear plane, in this plane

- ε c :

-

energy dissipated during one encounter of two particles bordering a shear plane

- ε p :

-

energy dissipated by one particle

- \(\dot \varepsilon \) :

-

energy dissipated per unit of volume and time during steady flow

- η :

-

viscosity

- η app :

-

\({\tau \mathord{\left/ {\vphantom {\tau {\dot \gamma }}} \right. \kern-\nulldelimiterspace} {\dot \gamma }}\) calculated as if the liquid is Newtonian

- η 0 :

-

viscosity of suspension medium

- η PL :

-

lim\(({\tau \mathord{\left/ {\vphantom {\tau {\dot \gamma }}} \right. \kern-\nulldelimiterspace} {\dot \gamma }})_{\dot \gamma \to \infty } \)

- [η]:

-

intrinsic viscosity

- η diff :

-

\({{d\tau } \mathord{\left/ {\vphantom {{d\tau } {d\dot \gamma }}} \right. \kern-\nulldelimiterspace} {d\dot \gamma }}\)

- η diff, rel :

-

η diff/η 0

- σ :

-

standard deviation of distribution ofy 0 values

- τ :

-

shear stress

- τ n :

-

average shear stress at the highest\(\dot \gamma \) values applied

- Ф :

-

mass average particle diameter

- Ф n :

-

number average particle diameter

- ϕ :

-

solid volume fraction

- ϕ eff :

-

effective solid volume fraction in Dougherty-Krieger relation

- ϕ max :

-

maximum solid volume fraction permitting flow

- ω i :

-

angular velocity of inner cylinder in rheometer during measurements

References

Firth BA, Hunter RJ (1976) J Coll Int Sci 57:266

van de Ven TGM, Hunter RJ (1977) Rheol Acta 16:534

Hunter RJ, Frayne J (1979) J Coll Int Sci 71:30

Hunter RJ (1982) Adv Coll Interface Sci 17:197

Ekdawi N, Hunter RJ (1983) J Coll Int Sci 94:355

Hunter RJ, Rheological and sedimentation behaviour of strongly interacting colloidal systems, in: Ficke HF (ed), Modern trends of colloid science in chemistry and biology, Birkhäuser Verlag 1985, p 18

Krieger M (1972) Adv Coll Int Sci 3:11

van Diemen AJG, Schreuder FWAM, Stein HN (1985) J Coll Int Sci 104:87

Schreuder FWAM, Stein HN (in press)

van Diemen AJG, Stein HN (1983) J Coll Int Sci 96:180

Stein HN, Colloids and surfaces (in press)

van Diemen AJG, Stein HN (1983) Rheol Acta 22:41

van Diemen AJG, Stein HN (1984) Powder Technology 37:275

Kao SV, Nielsen LE, Hill CT (1975) J Coll Int Sci 53:358, 367

Rautenbach R, Schlegel D (1969) Chem Ing Techn 41:369

Overbeek JThG, in: Kruyt HR, Colloid Science I, Elsevier Publ Corp 1952, p 270

Visser J (1972) Adv Coll Int Sci 3:331

Verweij EJW, Overbeek JThG (1948) Theory of the stability of cyophobic colloids. Elsevier Publ. Corp., Amsterdam, p 100

Batchelor GK, Green JT (1972) J Fluid Mech 56:375

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Schreuder, F.W.A.M., Stein, H.N. Rheology of concentrated coagulating suspensions in non-aqueous media. Rheol Acta 26, 45–54 (1987). https://doi.org/10.1007/BF01332683

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF01332683