Abstract

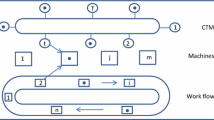

The paper considers the loading problem in flexible manufacturing systems (FMSs). This problem involves the assignment to the machine tools of all operations and associated cutting tools required for part types that have been selected to be produced simultaneously. The loading problem is first formulated as a linear mixed 0–1 program with the objective to minimize the greatest workload assigned to each machine. A heuristic procedure is presented in which an assignment of operations to machine tools is obtained by solving a parameterized generalized assignment problem with an objective function that approximates the use of tool slots required by the operations assigned to the machines. The algorithm is coded in FORTRAN and tested on an IBM-compatible personal computer. Computational results are presented for different test problems to demonstrate the efficiency and effectiveness of the suggested procedure.

Similar content being viewed by others

References

Baker, Kenneth R.,Introduction to Sequencing and Scheduling, John Wiley and Sons, New York (1974).

Bastos, José M., “Batching and Routing: Two Functions in the Operational Planning of Flexible Manufacturing Systems,”European Journal of Operational Research, Vol. 33, pp. 230–244 (1986).

Berrada, Mohammed and Kathryn E. Stecke, “A Branch and Bound Approach for Machine Load Balancing in Flexible Manufacturing Systems,”Management Science, Vol. 10, pp. 1316–1335 (1988).

de Werra, Dominique and M. Widmer, “Loading Problems with Tool Management in Flexible Manufacturing Systems: A Few Integer Programming Models,”International Journal of Flexible Manufacturing Systems, Vol. 3, No. 1, pp. 71–82 (1991).

Dietrich, B.L. and Laureano F. Escudero, “On Solving a 0–1 Model for Workload Allocation on Parallel Unrelated Machines with Set-Ups,” in Kathryn E. Stecke and Rajan Suri (Eds.),Proceedings of the Third ORSA/TIMS Conference on Flexible Manufacturing Systems: Operations Research Models and Applications, Elsevier Science Publishers B. V., Amsterdam, pp. 181–186 (1989).

Fisher, Marshall L. and Ramchandran Jaikumar, “A Generalized Assignment Heuristic for Vehicle Routing,”Networks, Vol. 11, pp. 109–124 (1981).

Fisher, Marshall L., Ramchandran Jaikumar, and Luk N. Van Wassenhove, “A Multiplier Adjustment Mcthod for the Generalized Assignment Problem,”Management Science, Vol. 32, No. 9, pp. 1095–1103 (1986).

Guignard, Monique and Kurt Spielberg, “Logical Reduction Methods in Zero-One Programming, Minimal Preferred Variables,”Operations Research, Vol. 29, No. 1, pp. 49–74 (1981).

Kim, Yeong-Dae and Candace Arai Yano, “An Iterative Approach to System Setup Problems in Flexible Manufacturing Systems,”International Journal of Flexible Manufacturing Systems, Vol. 4, No. 2, pp. 183–209 (1992).

Kuhn, Heinrich,Einlastungsplanung von Flexiblen Fertigungssystemen, Physica-Verlag, Heidelberg (1990).

Kusiak, Andrew, “Loading Models in Flexible Manufacturing Systems,” in A. Raouf and S.I. Ahmad (Eds.),Flexible Manufacturing: Recent Developments in FMS, Robotics, CAD/CAM, CIM, Elsevier Science, Amsterdam, pp. 119–132 (1985).

Kusiak, Andrew, “Application of Operational Research Models and Techniques in Flexible Manufacturing Systems,”European Journal of Operational Research, Vol. 24, pp. 336–345 (1986).

Martello, Silvano and Paolo Toth, “An Algorithm for the Generalized Assignment Problem,” in J.B. Brans (Ed.), Operations Research '81, North-Holland, Amsterdam, pp. 589–603 (1981).

Sarin, S.C. and C.S. Chen, “The Machine Loading and Tool Allocation Problem in a Flexible Manufacturing System,”International Journal of Production Research, Vol. 7, pp. 1081–1094 (1987).

Stecke, Kathryn E., “Formulation and Solution of Nonlinear Integer Production Planning Problems for Flexible Manufacturing Systems,”Management Science, Vol. 29, No. 3, pp. 273–288 (1983).

Stecke, Kathryn E., “A Hierarchical Approach to Solving Machine Grouping and Loading Problems of Flexible Manufacturing Systems,”European Journal of Operational Research, Vol. 24, pp. 369–378 (1986).

Stecke, Kathryn E., “Algorithms for the Efficient Planning and Operation of a Particular FMS,”International Journal of Flexible Manufacturing Systems, Vol. 1, No. 4, pp. 287–324 (1989).

Stecke, Kathryn E. and Ilyong, Kim, “A Study of FMS Part Type Selection Approaches for Short-Term Production Planning,”International Journal of Flexible Manufacturing Systems, Vol. 1, No. 1, pp. 7–29 (1988).

Stecke, Kathryn E. and F. Brian Talbot, “Heuristics for Loading Flexible Manufacturing Systems,” in A. Raouf and S.I. Ahmad (Eds.),Flexible Manufacturing: Recent Developments in FMS, Robotics, CAD/CAM, CIM, Elsevier Science Publishers B.V., Amsterdam, pp. 73–85 (1985).

Suri, Rajan and Cynthia K. Whitney, “Decision Support Requirements in Flexible Manufacturing,”Journal of Manufacturing Systems, Vol. 1, pp. 61–69 (1984).

Tempelmeier, Horst and Heinrich Kuhn,Flexible Manufacturing Systems—Decision Support for Design and Operation, John Wiley and Sons, New York (1993).

Trick, Michael A., “A Linear Relaxation Heuristic for the Generalized Assignment Problem,”Naval Research Logistics, Vol. 39, No. 2, pp. 137–151 (1992).

Van Looveren, A.J., L.F. Gelders, and Luk N. Van Wassenhove, “A Review of FMS Planning Models,” in Andrew Kusiak (Ed.),Modelling and Design of Flexible Manufacturing Systems, Elsevier Science Publishers B.V., Amsterdam, pp. 3–31 (1986).

Whitney, Cynthia K. and T.S. Gaul, “Sequential Decision Procedures for Batching and Balancing in FMSs,”Annals of Operations Research, Vol. 3, pp. 301–316 (1985).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Kuhn, H. A heuristic algorithm for the loading problem in flexible manufacturing systems. Int J Flex Manuf Syst 7, 229–254 (1995). https://doi.org/10.1007/BF01325036

Issue Date:

DOI: https://doi.org/10.1007/BF01325036