Abstract

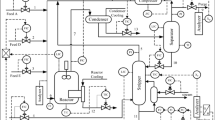

A process fault identification and classification scheme for an automobile door assembly process is presented based on multivariate in-line dimensional measurements and principal component factor analysis. First, the door assembly process and the dimensional measurement system are briefly introduced. Second, the technique of principal component factor analysis is presented for process fault identification. Process faults are summarized based on off-line identified case studies. Finally a machine classification scheme based on principal components and principal factors is presented and evaluated, using the pattern knowledge obtained off-line. This scheme is shown to be effective in classifying process faults using production data.

Similar content being viewed by others

References

Gorsuch, R.L.,Factor Analysis, Lawrence Erlbaum Associates, Publishers (1983).

Hotelling, H., “Multivariate Quality Control,” inTechniques of Statistical Analysis, C. Eisenhart, M. Hastay, and W.A. Wallis (Eds.), New York (1947).

Hu, S.J. and Wu, S.M., “Identifying Root Causes of Variation in Automobile Body Assembly Using Principal Component Analysis,”Transactions of North America Manufacturing Research Institution, pp. 311–316 (May 1992).

Jackson, J.E., “Principal Component and Factor Analysis: Part I—Principal Components,”Journal of Quality Technology, Vol. 12, No. 4, pp. 201–213 (October 1980).

Manly, B.F.J.,Multivariate Statistical Methods—A Primer, Chapman and Hall, New York (1986).

Therrien, C.W.,Decision Estimation and Classification—An Introduction to Pattern Recognition and Related Topics, John Wiley and Sons, New York, NY (1989).

Thurstone, L.L.,Multiple Factor Analysis, University of Chicago Press, Chicago, IL (1947).

Wang, W.W., “Accuracy Analysis for In-Line OCMM.” Ph.D. Thesis, Department of Mechanical Engineering and Applied Mechanics, The University of Michigan, Ann Arbor, MI (1991).

Wu, S.K., “A Methodology for Optimal Door Fit in Automobile Body Manufacturing.” Ph.D. Thesis, Department of Mechanical Engineering and Applied Mechanics, The University of Michigan, Ann Arbor, MI (1991).

Wu, S.K., Hu, S.J., and Wu, S.M., “Optimal Door Fitting with Systematic Fixture Adjustment,”International Journal of Flexible Manufacturing Systems, Vol. 6, No. 2, (1994).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Wu, SK., Hu, S.J. & Wu, S.M. A fault identification and classification scheme for an automobile door assembly process. Int J Flex Manuf Syst 6, 261–285 (1994). https://doi.org/10.1007/BF01324797

Issue Date:

DOI: https://doi.org/10.1007/BF01324797