Conclusions

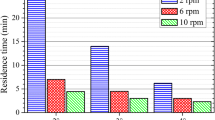

The current of the drive and consequently the power consumption of rotary kilns 4.5 m in diameter and 170 m in length decrease with an increase in the rotary speed of the kiln. The open porosity of the sintered magnesite powder decreases only slightly in this case but the grain-size distribution of the powder undergoes a change.

A decrease in the grain size of the raw magnesite results in more rapid dissociation and sintering and in a significant improvement in the cost-effectiveness indices of the performance of rotary kilns: the productivity increases and dust entrainment, the coefficient of raw material consumption, and specific fuel consumption decrease without a decrease in the density of the sintered powder.

In a rotary kiln 3.5 m in diameter and 90 m in length, when firing the magnesite 0–15-mm fraction in place of the usual 0–40-mm fraction, the productivity of the kiln increases by 5–8% and the coefficient of raw material consumption and the specific fuel consumption decreases by 5–7 and 5–8%, respectively, in addition to which the sintered powder contains 4–5% more of the 3–0.5-mm fraction, which is used for refractories production.

For firing magnesite in the form of the 0–15-mm fraction in place of the usual 0–40-mm fraction on a large scale, the crushing-beneficiation mills (the third crushing stage) must be modified with a view to utilizing mainly magnesite grades 1 and 2 as well as magnesite enriched in heavy suspensions.

Similar content being viewed by others

Literature cited

K. V. Simonov, P. V. Cherepov, A. G. Luzin, et al., Ogneupory, No. 9, 35–44 (1973).

G. S. Val'berg, I. K. Griner, and V. Ya. Mefodovskii, Faster Cement Production [in Russian], Stroiizdat, Moscow (1971).

V. I. Goncharov, in: Theoretical and Technological Investigations in the Field of Refractories, Trans. Ukr. Inst. Refract. [in Russian], No. 14, Metallurgiya, Moscow (1971), pp. 294–299.

Author information

Authors and Affiliations

Additional information

Translated from Ogneupory, No. 12, pp. 14–18, December, 1976.

Rights and permissions

About this article

Cite this article

Simonov, K.V., Cherepov, P.V., Luzin, A.G. et al. The grain-size distribution of the raw magnesite and the rotary speed of the kiln as factors in the kiln performance and the quality of the powder. Refractories 17, 736–740 (1976). https://doi.org/10.1007/BF01319880

Issue Date:

DOI: https://doi.org/10.1007/BF01319880