Abstract

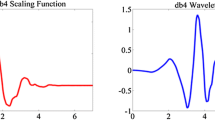

This paper presents a real-time tool breakage detection method for small diameter drills using acoustic emission (AE) and current signals. Using the transmitted properties of the AE signal, apparatus for detecting the AE signal for tool breakage monitoring was developed for a machine centre. The features of tool breakage were obtained from the AE signal using typical signal processing methods. The continuous wavelet transform (CWT) and the discrete wavelet transform (DWT) were used to decompose the spindle current signal and the feed current signal, respectively. The tool breakage features were extracted from the decomposed signals. Experimental results show that the proposed monitoring system possessed an excellent real-time capability and a high success rate for the detection of the breakage of small diameter drills using combined AE and current signals.

Similar content being viewed by others

References

A. Dornfeld, “Neural network sensor fusion for tool condition monitoring”, Annals CIRP, 39, pp. 101–1051, 1990.

Li Dan and J. Mathew, “Tool wear and failure monitoring techniques for turning-A review”, International Journal of Machine Tools Manufacturing, 30(4), pp. 579–598, 1990.

G. Byrne, D. Dornfeld, et al., “Tool condition monitoring (TCM) — the status of research and industrial application”, Annals CIRP, 44(2), pp. 541–567, 1995.

K. F. Marti, J. A. Brandon, B. I. Grosvenor and A. Dwen, “A comparison of in-process tool wear measurement methods in turning”, Proceedings 26th International Machine Tool Design and Research Conference, pp. 289–296, 1986.

A. Novak and G. Ossbahr, “Reliability of the cutting force monitoring in FMS-instatations”, Proceedings 26th International Machine Tool Design and Research Conference, pp. 325–329, 1986.

I. Daubechies, “The wavelet transform, time-frequency localization and signal analysis”, IEEE Transactions on Information Theory, 36(5), pp. 961–1005, 1990.

I. Daubechies, “Orthogonal bases of compactly supported wavelets”, Communications on Pure and Applied Mathematics, 41, pp. 909–996, 1988.

Ibrahim Nur Tansel et al., “Detection of tool failure in end milling with wavelet transformations and neural networks (WT-NN)”, International Journal of Machine Tools Manufacturing, 35(4), pp. 1137–1147, 1995.

I. N. Tansel, C. Mekdeci, O. Rodriguez and B. Uragun, “Monitoring drill conditions with wavelet based encoding and neural network”, International Journal of Machine Tools Manufacturing, 33(4), pp. 559–575, 1995.

N. Kasashima, et al., “Real-time failure detection in face milling using discrete wavelet transform”, Annals CIRP, 44(1), pp. 483–487, 1995.

Takaaki Nagao, Yotaro Hatamura and Mamoru Mitsuishi, “Inprocess prediction and prevention of the breakage of small diameter drills — based on theoretical analysis”, Annals CIRP, 43(1), pp. 85–88, 1994.

Olivier Rioul and Pierre Duhamel, “Fast algorithms for discrete and continuous wavelet transforms”, IEEE Transactions on Information Theory, 38(2), March 1992.

G. Evangelisto, “Orthogonal wavelet transforms and filter banks”, Presented at Proceedings 23rd Asilomar Conference, IEEE, November 1989.

Li Xiaoli, Yao Yingxue and Yuan Zhejun, “Experimental investigation of acoustic emission signal transmitted properties and application”, High Technology Letter (accepted).

Li Xiaoli, Yao Yingxue and Yuan Zhejun, “On-line tool condition monitoring system with wavelet fuzzy neural network”, Journal of Intelligent Manufacturing, 8(4), pp. 271–276, 1997.

Li Xiaoli, Yao Yingxue and Yuan Zhejun, “Development of monitoring system for cutting tool failure on machining centre”, 1, pp. 11–14, 1997.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, X. Real-time detection of the breakage of small diameter drills with wavelet transform. Int J Adv Manuf Technol 14, 539–543 (1998). https://doi.org/10.1007/BF01301696

Issue Date:

DOI: https://doi.org/10.1007/BF01301696