Conclusions

An analysis was carried out of the method of preparing the SnO2 as a factor in the degree of sintering of the cassiterite refractory.

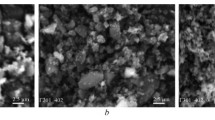

Grinding fired and unfired SnO2 in a vibro-mill increases the degree of dispersion of the material; an increase in the proportion of grains finer than 10μ results in an increase in the density of the green product. The proportion of iron grinidings is significantly smaller with unfired than with fired SnO2.

The porosity and density of the sintered specimens depends on the fineness of the ground SnO2.

Specimens molded from pure tin oxide whether or not fired and ground undergo only marginal compaction when heated to 1600°C, i.e., the porosity of the specimens depends solely on the porosity of the green product. However, the strength of the specimens which to a certain extent depends on the porosity, increases in this case. Starting at 1600°C the growth of the SnO2 crystals caused the strength of some of the specimens to decrease.

Similar content being viewed by others

Literature cited

G. V. Samsonov (editor), Physicochemical Properties of Oxides. Reference Manual [Russian translation] Metallurgiya, Moscow (1969).

H. Remy, Treatise on Inorganic Chemistry, Vol. 1, Am. Elsevier (1956).

Refractory Materials for Optical-Glass Furnaces. Abstracts of Reports [in Russian], TsNIIinformatsiya, Moscow (1973).

I. E. Cambell, High-Temperature Engineering [Russian translation], IL, Moscow (1959).

S. A. Dzhumagulov, Yu. A. Kondrat'ev, V. K. Pavlovskii, et al., Zh. Prikl. Khim.,46, No. 11, 2428–2432 (1973).

V. Susser, Glastechn. Ber.,42, No. 11, 457–460 (1969).

E. K. Begley, Ceramic Industry,93, No. 2, 53–55 (1969).

T. A. Zhuravina, T. T. Petrovskii, I. G. Mel'nikova, et al., Opt.-Mekh. Prom., No. 5, 33–37 (1972).

V. A. Kolbasova, I. N. Abramova, L. Kh. Bekker, et al., in: Electronic Engineering (Scientific-Technical Essays) [in Russian], Moscow (1972).

I. S. Kainarskii and É. V. Degtyareva, Ogneupory, No. 10, 37–41 (1971).

N. A. Toropov, V. P. Barzakovskii, I. A. Bondar', and Yu. P. Udalov, Phase Diagrams of Silicate Systems. Reference Manual [in Russian], No. 2, Nauka, Leningrad (1970).

S. E. Andreev, V. V. Tovarov, and V. A. Petrov, Grinding Theory and the Calculation of the Characteristics of a Granulometric Composition [Russian translation], Metallurgizdat, Moscow (1959).

Author information

Authors and Affiliations

Additional information

Translated from Ogneupory, No. 5, pp. 37–42, May, 1977.

Rights and permissions

About this article

Cite this article

Degtyareva, É.V., Kabakova, I.I. & Drozd, V.I. The method of preparing the tin dioxide as a factor in the sintering of the cassiterite refractory. Refractories 18, 289–293 (1977). https://doi.org/10.1007/BF01294080

Issue Date:

DOI: https://doi.org/10.1007/BF01294080