Conclusions

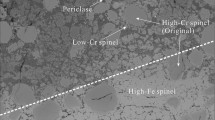

The periclase in chrome-magnesite containing iron oxides in its composition in the form of solid solutions secretes them during service in the sintering zone of rotary kilns, becomes lighter, recrystallizes, increasing in size through the intergrowth of several neighboring grains within the aggregates. The longer the refractory remains in the furnace, the more marked this effect.

It is incorrect to transfer mechanically the metallurgical explanation of the brown fringe on the periclase aggregates and consider it to be a sign of their saturation with iron oxide.

The recrystallization of the periclase is a positive factor furthering the service life of the refractory.

Similar content being viewed by others

References

N. V. Il'yina. Proc. Giprotsementa, 1950, issue XIII.

Ya. V. Klyucharov and others. Proc. Giprotsementa, 1956, issue XIX.

Ya. V. Klyucharov and other. Cement, 1952, No. 6.

D. S. Belyankin and other. Proc. Petrographic Institute of AS USSR, 1957, issue 11.

D. S. Belyankin and others. Petrography of technical stone. Acad. Sci. Press, Moscow, 1952.

D. S. Belyankin. Selected works, Vol. 1, Academy of Sciences Press, Moscow, 1956.

D. S. Belyankin and other. Ogneupory, 1949, No. 2.

D. S. Belyankin, Proc. of Petrographic Institute of AS USSR, 1938, issue 13.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Sharafiyev, M.S., Orlova, G.V. Periclase in chrome-magnesite lining of rotary kiln for firing cement clinker. Refractories 3, 111–112 (1962). https://doi.org/10.1007/BF01293167

Issue Date:

DOI: https://doi.org/10.1007/BF01293167