Conclusions

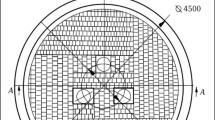

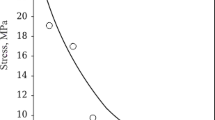

A method has been developed and tested for increasing the durability of the lining of 420-ton mixer type transfer ladles for cast iron by the impregnation of the active layer with tar. At a tar temperature of 100°C the active layer is fully impregnated in 65 h. The result is a decrease in the porosity and increase in the coldcrushing strength of the chamotte brick. For a good-quality impregnation use must be made of a steam coil which will heat the tar evenly throughout the ladle volume to 100–120°C.

The impregnation increased the durability of the ladle lining from 316 to 400 transfers.

Similar content being viewed by others

Author information

Authors and Affiliations

Additional information

Translated from Ogneupory, Vol. 18, No. 8, pp. 29–31, August, 1977.

Rights and permissions

About this article

Cite this article

Ashpin, B.I., Peshkov, V.R., Sleptsov, Z.E. et al. Durability of the lining of mixer-type transfer ladles. Refractories 18, 469–471 (1977). https://doi.org/10.1007/BF01288256

Issue Date:

DOI: https://doi.org/10.1007/BF01288256