Conclusions

The large, complex-shaped Dinas refractory products for coke ovens should be fired in a specialized tunnel kiln equipped with burners (of the roof or wall type) which will ensure a high degree of firing uniformity. The effective height of the kiln charge should preferably be about 700 mm. The charge should be set up in well-spaced columns and the products should be placed predominantly on their ends. The lining of the floor of the kiln or kiln trucks should be constructed of lightweight refractories and heat-insulating materials.

Complex-shaped Dinas products should be produced from compositions with a maximum grain size of 2 mm and the grain-size distribution given earlier in this article.

The mineralizing additive should be ferrous lime with CaO/FeO=1.8/0.7, and the amount added to the composition should be 2.5±0.1%.

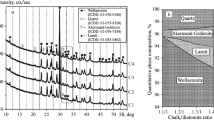

To maximize the precision of the dimensions of the product and to minimize its aftergrowth the proportion of unconverted quartz should not exceed 2%. This condition can be ensured by using a fine-grained molding mix and the correct amount of an additive of the correct composition and by optimizing the firing conditions in the specialized kiln.

Similar content being viewed by others

Literature cited

I. S. Kainarskii and B. E. Pindrik, Ogneupory, No. 8, 339–353 (1952).

V. D. Tsigler, S. S. Bovkun, Yu. P. Sidorenko, et al., Ogneupory, No. 1, 19–25 (1959).

S. S. Bovkun and Yu. P. Sidorenko, Ogneupory, No. 9, 399–402 (1961).

S. A. Shiryaev, I. T. Gubko, I. D. Sizov, et al., Ogneupory, No. 6, 10–19 (1968).

S. A. Shiryaev, Ogneupory, No. 8, 22–25 (1969).

M. Z. Shvartsman, I. P. Tsibin, I. T. Gubko, et al., Ogneupory, No. 4, 17–23 (1974).

I. S. Kainarskii and V. A. Bron, Ogneupory, No. 12, 827–841 (1937).

I. S. Kainarskii and V. A. Bron, Ogneupory, No. 9, 1413–1424 (1938).

V. D. Tsigler, Byull. Nauchno-Tek. Inf. VNIIO, No. 3, 44–56 (1958).

I. F. Usatikov, V. L. Bulakh, A. A. Eltysheva, et al., Ogneupory, No. 7, 8–12 (1974).

I. S. Kainarskii, É. V. Degtyareva, and I. G. Orlova, Ogneupory, No. 12, 41–46 (1972).

A. V. Zhukov, F. V. Filimonov, and N. A. Tyutin, Ogneupory, No. 3, 25–31 (1974).

V. G. Abbakumov, G. A. Tarakanchikov, G. Sh. Ashkinadze, et al., Ogneupory, No. 10, 11–17 (1972).

L. Chomat, Inter. Ceram.,21, No. 4, 281 (1972).

M. Z. Shvartsman, Ogneupory, No. 8, 375–381 (1953).

S. Freund and R. Rittmann, Keram. Z.,27, No. 3, 131–134 (1975).

S. Hempel and K. Stockmann, Silikattechnik,24, No. 2, 45–50 (1973).

O. P. Ostrovskii, V. E. Kornienko, and N. G. Shklyarenko, Steklo Keram., No. 5, 32–35 (1968).

O. P. Ostrovskii, V. G. Goncharenko, A. N. Ostrovskii, et al., Byull. Inst. Chermetin., No. 2, 58–59 (1972).

W. Harms, Inter. Ceram.,23, No. 2, 101–106 (1974).

G. A. Kovel'man and A. A. Barenboim, Steklo Keram., No. 10, 20–21 (1974).

G. Bouwman, Silicates Inds.,11, No. 12, 377–380 (1972).

H. Bouwman, Inter. Ceram.,22, No. 1, 60–63 (1973).

Refractories J.,44, No. 11, 13a (1968).

V. G. Abbakumov, Ogneupory, No. 9, 21–30 (1975).

V. G. Abbakumov and M. S. Glazman, Ogneupory, No. 10, 17–23 (1975).

J. H. Chesters, Refractories: Production and Properties, Iron and Steel Inst., London (1973).

R. Lenz, Inter. Ceram.,24, No. 2, 111–116 (1975).

I. S. Kainarskii, in: Proceedings of the Third All-Union Conference on Refractory Materials [in Russian], Izd. Akad Nauk SSSR, Moscow-Leningrad (1947), pp. 34–42.

I. S. Kainarskii, Dinas [in Russian], Metallurgizdat, Moscow (1961).

A. I. Avgustinik and O. K. Kurdevanidze, Zh. Prikl. Khim.,19, No. 10–11, 1189–1196 (1946).

V. A. Bron and I. P. Bas'yas, Ogneupory, No. 1, 17–24 (1946).

A. A. Eltysheva and I. S. Kainarskii, Ogneupory, No. 3, 118–131 (1958).

I. S. Kainarskii and M. D. Shcheglova, Ogneupory, No. 4, 173–178 (1957).

I. S. Kainarskii and I. G. Orlova, Sb. Nauchn. Tr., Ukr. Nauchno-Issled. Inst. Ogneuporov, No. 3 (50), 70–108 (1960).

Additional information

Translated from Ogneupory, Vol. 18, No. 8, pp. 9–16, August, 1977.

Rights and permissions

About this article

Cite this article

Kainarskii, I.S. Firing of large intricately shaped Dinas products. Refractories 18, 449–457 (1977). https://doi.org/10.1007/BF01288250

Issue Date:

DOI: https://doi.org/10.1007/BF01288250