Summary

The combined addition of hydrophobic organic liquids and mineral (refractory) additions improves the structure and physico-mechanical properties of fireclay refractories. The spalling resistance is greatly increased.

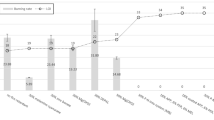

The spalling resistance of fireclay specimens assessed by the number of heat cycles before destruction with the combined action of mazut and mineral additives is 2.0–2.8 times greater than with the manufacture of the articles without these additives.

The increase in spalling resistance occurs owing to the development of microcracks in the structure around the grains of grog, with a simultaneous reduction in the modulus of elasticity and coefficient of thermal expansion and also an increase in deformation before failure (σ/E) of the material.

The addition to the hydrophobic organic liquid (mazut) of fine powders (magnesite, alumina) permits not only a considerable increase in spalling resistance, but also a certain reduction in the porosity and an increase in the strength of the products.

Separate introduction of the additives (mazut on the grog, magnesite and kaolin to the bond) gives worse results compared with the above method (lower spalling resistance, increased expansion).

Thus it was shown that the main factor determining the resistance of fireclay refractories against thermal strains is the nature of the contacts of the surfaces of the grains of grog and the bond.

Semiplant testing of the method showed that the addition of 5% mazut and 5% calcined kaolin (or magnesite) doubled the life of fireclay saggers.

Similar content being viewed by others

Literature cited

R. King and G. Ewans, Journ. Amer. Cer. Soc, 12. No. 8 (1933).

M. Bykhovskii, Keramika i Steklo, No. 4 (1934).

R. A. Heindl, Ceramic Age, 45, No. 10 (1935).

P. P. Budnikov and E. L. Mendel'grin, ZhPKh, 5, No. 3–4 (1932).

É. K. Keler, Determination of elastic and residual shear deformation of ceramics. Gizmestprom, Moscow-Leningrad (1939).

K. Konopicky, Stahl and Eisen, 61, No. 3 (1941).

A. P. Panarin, Ogneupory, No. 6 (1946).

P. P. Budnikov and V. I. Khramova, UKhZh, 20, No. 4 (1954).

I. S. Kainarskii and É. V. Degtyareva, Collection of Sci. Papers, UNIIO, No. 4 (1960).

P. S. Mamykin, Ogneupory, No. 9 (1947).

G. V. Kukolev and I. I. Nemets, Ogneupory, No. 2 (1963).

G. V. Kukolev, et al., Steklo i Keramika, No. 9 (1962).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Kukolev, G.V., Nemets, I.I. Increasing the spalling resistance of fireclay refractories by adding combustible organic liquids and m ineral a dditives. Refractories 5, 216–224 (1964). https://doi.org/10.1007/BF01287588

Issue Date:

DOI: https://doi.org/10.1007/BF01287588