Conclusions

Production tests showed that the wear of the blocks made of refractory concretes based on periclase cement and on Portland cernent in the walls of vertical channels, in the back wall and in the front columns of open-hearth furnaces does not exceed the wear of structures of refractory brick.

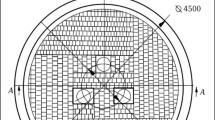

It would be advantageous to continue tests on blocks of refractory concretes in open-hearth furnaces by extending the scale of the trials. The sizes of the blocks should be increased and their weight brought to three tons.

For the large-scale use of large blocks of refractory concrete in open-hearth furnaces it is necessary to organize the plant manufacture of all components and to mechanize repair operations.

Similar content being viewed by others

Author information

Authors and Affiliations

Additional information

A classification of refractory concretes was given in “Ogneupory” No. 5 for 1960 and in SNiP part I, section B, chapter 3, p. 11, Gosstroiizdat, 1963 [in Russian].

Rights and permissions

About this article

Cite this article

Shakhlin, V.I., Shunin, T.G., Tarasov, A.F. et al. Experience with the use of refractory concretes in structural components of open hearth furnaces. Refractories 4, 395–398 (1963). https://doi.org/10.1007/BF01285134

Issue Date:

DOI: https://doi.org/10.1007/BF01285134