Conclusions

The proposed vacuum furnace makes it possible to determine the deformation temperature under load and the coefficient of thermal expansion to high temperatures.

Ceramics of pure oxides, Al2O3, ZrO2, MgO, and BeO, have high temperatures of softening under load. The temperature of initial softening of Al2O3 ceramics containing additives lies in the range 1860–1930°C. The magnesia and beryllia specimens show high softening temperatures under load, but in vacuum at high temperatures they are very volatile. The initial softening temperature of ZrO2 is about 2250°C.

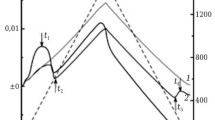

The linear expansion of pure-oxide ceramics reaches 2–3% at 1800–2000°C. Values obtained for the average coefficients of expansion for Al2,O3, ZrO2, MgO, and BeO are little different from those in the literature.

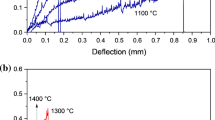

The compressive strength and bending strength of pure oxides at high temperatures are relatively low. The highest obend at high temperatures is possessed by specially pure zirconia, stabilized with MgO. Magnesia and beryllia in compressive strength at high temperatures exceed the other oxides.

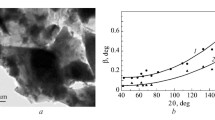

The highest spalling resistance is shown by beryllia ceramics. The combined addition to alumina of 1% TiO2 and 5% ZrO2 leads to a reduction in sintering temperature and an increase in thermal shock resistance. Ceramics based on specially pure zirconia stabilized with an optimum amount of CaO and MgO show a high thermal shock resistance.

Similar content being viewed by others

Literature cited

E. Ryschkewitsch, Ber. Deutsch. Ker. Ges.,22, 54–55 (1941).

E. Ryschkewitsch, Oxydkeramik der Einstoffsytem Standpunkt der Physikalischen Chemie, Berlin (1948).

E. Ryschkewitsch, Oxide ceramics (1960).

W. Kingery, Journ. Amer. Cer. Soc., No. 1 (1955).

High Temperature Investigation, Published by Foreign Literature Press [in Russian] (1962).

P. P. Budnikov, et al., Technology of Ceramics and Refractories, Gosstroiizdat [in Russian] (1962).

S. G. Tresvyatskii and A. M. Cherepanov, High-temperature materials and oxide products, Metallurgizdat [in Russian], pp. 168–169 (1957).

High Temperature Technology, published by the Foreign Literature Press [in Russian] (1959).

N. M. Pavlushin, Corundum, Gosstroiizdat [in Russian] (1961).

D. N. Poluboyarinov, et al., High-AluminaCeramic and Refractory Materials, Gosstroiizdat (1960).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Lukin, E.S., Poluboyarinov, D.N. Some thermomechanical properties of pure oxide ceramics. Refractories 4, 347–352 (1963). https://doi.org/10.1007/BF01285119

Issue Date:

DOI: https://doi.org/10.1007/BF01285119