Conclusions

At the Zhdanov Metallurgical Factory for fusing sections of local burnouts in the linings of 130 ton oxygen converters use is now being made of flame guncreting. The guncreting extends the converter campaign by 20–135 heats with a guncrete body consumption of 0.5–1.5 kg/ton of steel.

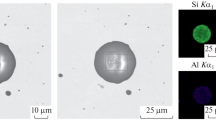

The electron microscope was used to study the shape of the particles of guncrete body taken from the gases escaping during guncreting. The sintering of the particles in the flame is rapid. In connection with this there is no need to warm up the guncrete coating after its application to the lining, which, taking into account the specific features of the oxygen converter technique, is an important advantage of the described technology.

Petrographic studies of the changed zones in the specimens of the guncrete coatings after service in the converter showed the presence of an increased quantity of fusible components. A study of the zones in the guncrete coatings in a laser microspectral analyzer showed the smooth nature of the distribution of the iron oxides across the thickness of the layer. Due to this the guncrete coating does not scale, but wears out due to slag corrosion.

Similar content being viewed by others

Literature cited

A. P. Kudrina and G. F. Gul'ev, Refractories for Oxygen Converters [in Russian], Metallurgiya (1966), pp. 42–45.

V. K. Didkovskii et al., Collection from DonNIIchermet, Production of Steel, No. 19, Metallurgiya (1970), pp. 43–48.

V. A. Lazovskii, Guncreting Metallurgical Furnaces [in Russian], Metallurgiya (1968), pp. 47–51.

C. E. Brownlee, J. Metals,17, No. 7, 806–807 (1965).

L. Halm and C. Roedener, Circ. Inform. Techn. Center. Docum. S. Der.,25, No. 4, 971 (1968).

O. N. Chemeris et al., Collection from DonNIIchermet, Production of Steel, No. 19, Metallurgiya (1970), pp. 48–52.

O. N. Chemeris et al., Ogneupory, No. 4, 25–30 (1971).

I. A. Yuzefovskii et al., Bull. Inst. Chermetinformatsiya, No. 20, 32–33 (1971).

Ya. E. Geguzin, Physics of Sintering [in Russian], Nauka (1967), pp. 67–75, 90–91.

A. N. Pilyankevich, Practical Electron Microscopy: Methods of Preparation [in Russian], Mashgiz, Moscow-Kiev (1961), pp. 24–25.

G. Menke and L. Menke, Introduction to Laser Emission Microspectral Analysis [Russian translation], Mir (1968), pp. 36, 111.

V. V. Pustovalov, Thermal Conductivity of Refractories [in Russian], Metallurgiya (1966), pp. 76–88.

Author information

Authors and Affiliations

Additional information

Translated from Ogneupory, No. 11, pp. 23–29, November, 1972.

Rights and permissions

About this article

Cite this article

Chemeris, O.N., Didkovskii, V.K., Rebrov, L.V. et al. Flame guncreting of converter linings. Refractories 13, 710–715 (1972). https://doi.org/10.1007/BF01284114

Issue Date:

DOI: https://doi.org/10.1007/BF01284114