Conclusions

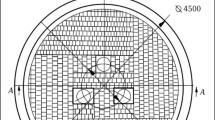

Compositions of thermal-insulation concrete mixtures from which various elements of the lining of a furnace for pyrolysis of dichlorethane were produced have been developed. Burner blocks for the gas burners of the furnace were produced by vibrocasting.

The refractories developed have provided reliable operation of the furnace, and for three years they have been in good condition.

Similar content being viewed by others

Literature cited

V. V. Primachenko, Ogneupory, No. 11, 39–41 (1987).

V. V. Primachenko, N. V. Pitak, L. M. Kolesnikov, et al., The Production of Special Refractories: A Subject Industry Collection [in Russian], No. 6, Metallurgiya, Moscow (1978).

V. V. Primachenko, L. M. Kolesnikov, T. A. Zadorozhnaya, et al., Technological and Methodological Investigations of Refractories [in Russian], Metallurgiya, Moscow (1988), pp. 4–7.

Author information

Authors and Affiliations

Additional information

Translated from Ogneupory, No. 7/8, pp. 27–29, July–August, 1992.

Rights and permissions

About this article

Cite this article

Fedoruk, R.M., Pitak, N.V., Gud', O.T. et al. Refractory lining of a furnace for pyrolysis of dichlorethane. Refractories 33, 393–396 (1992). https://doi.org/10.1007/BF01283306

Issue Date:

DOI: https://doi.org/10.1007/BF01283306